Continental announces improved sensor for electric drives

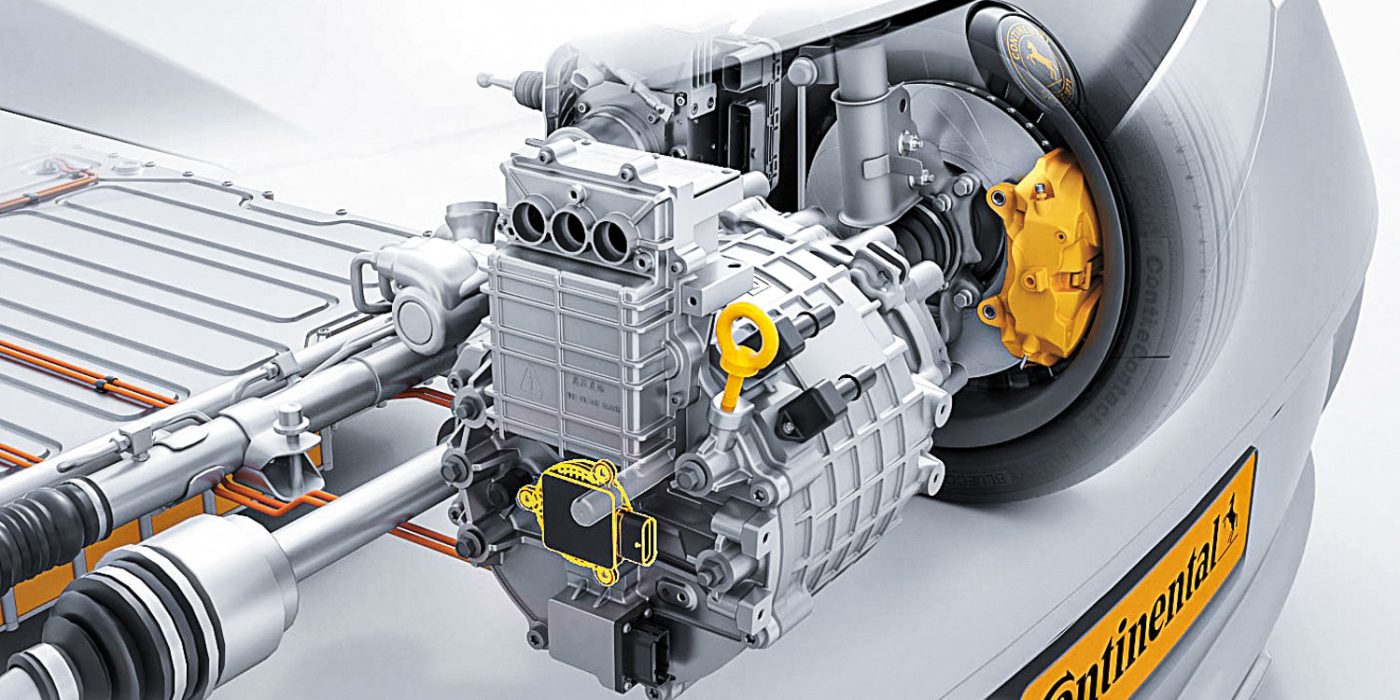

Continental is expanding its sensor portfolio for the electromobility market with the new inductive high-speed electric drive rotation position sensor (eRPS). This detects the exact position of the rotor in an electric synchronous motor.

According to the supplier, existing solutions for rotation measurement are often based on the resolver principle (a rotating electrical transformer). This is a complicated system that has to be specially adapted for each synchronous motor design.

The eRPS is a standardised component that is suitable for every drive system, regardless of the number of pole pairs. According to Continental, this new sensor can be easily transferred from one motor to another. Compared to existing resolver sensors, the eRPS is more compact, 40 per cent lighter and much more robust. The sensor design is based on the eddy current principle and is optimised to increase robustness against mechanical tolerances.

According to the automotive supplier, this contributes to an increase in efficiency and enables smoother operation. Unlike weight, however, the improvement in efficiency is not precisely quantified.

In synchronous motors, the rotor rotates at the same speed as the rotating field in the stator – as the name suggests, synchronously. In order to achieve maximum efficiency of the motor, the motor control must know the exact position of the rotor – which, according to Continental, makes this sensor design “an essential component of synchronous motor applications”. The electrical angular position data is thus needed for efficient torque control of the e-machine and to achieve the longest possible motor life.

The eRPS, which is significantly flatter than the resolver, supports “compact motor designs with a short overall length”. Continental plans to offer the eRPS in several configurations so that it can be placed in different locations. According to the company, the sensor can be mounted through the rotor shaft or at the end of the shaft, in this case even with a sealing function. At the same time, the sensor is also said to be suitable for high engine speeds of up to around 24,000 rpm.

“The growth in vehicle electrification translates into more synchronous motors in the car. This ranges from big and powerful ones like traction motors to smaller ones like electric pumps. Our standardized eRPS technology has a wide range of potential applications in electric vehicles,” said Laurent Fabre, head of the Passive Safety and Sensorics segment at Continental. “Measurement precision, compact dimensions and the all-in-one sensor concept combining several functions add to a high level of integration in the car.”

The start of production is planned for the end of 2025. Continental says it is one of the leading suppliers of engine position sensors today. With the introduction of the eRPS, Fabre says it is “well positioned to become one of the leading suppliers of position sensors for electric motors as well”.

0 Comments