BASF & TAT to cooperate on battery recycling in Germany

BASF has agreed on a long-term cooperation with the Israeli company Tenova Advanced Technologies (TAT) for its prototype plant for battery recycling in Schwarzheide, Brandenburg. Together, the two companies want to optimise the hydrometallurgical recycling process.

TAT’s novel process for the recovery of lithium, which includes lithium solvent extraction (LiSX) and lithium electrolysis (LiEL), is to be used. However, the communication does not describe this process in more detail. It only states that Tenova’s technology enables “efficient recovery of lithium from spent batteries and waste from battery production”.

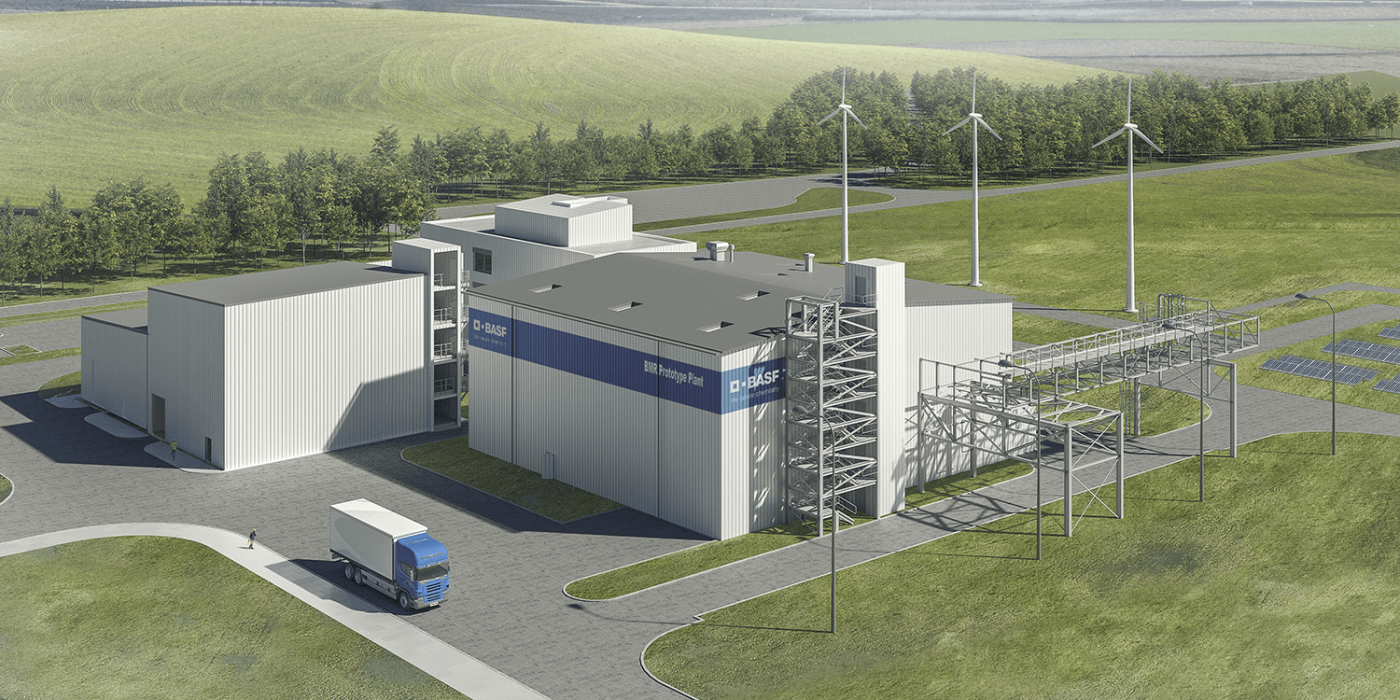

The commissioning of the prototype plant, for which BASF published details in June 2021, is planned for this year. In June 2022, BASF also announced that it would also build a plant for recycling black mass from batteries on an industrial scale in Schwarzheide, which is scheduled to come on stream in early 2024.

“Using recycled metals for production of new battery materials can reduce the CO2 emission impact of batteries by about 25 percent compared to the use of virgin metals,” says Daniel Schönfelder, Head of Battery Base Metals and Recycling at BASF. “We will close the loop from end-of-life batteries to new battery production and will ensure an exceptionally low CO2 footprint for key metals needed to meet the growing demand for eMobility.” According to Schönfelder, BASF hopes to test “new approaches in further optimizing the recycling process” from its collaboration with Tenova.

Irad Rekem, managing director of TAT, says: “We are proud to bring our expertise and innovative technologies to this collaborative effort with BASF to recycle end-of-life batteries. This will be a recycling process that will demonstrate efficient metal recovery and production of lithium salts based on solvent extraction.”

0 Comments