EVE Energy is expanding battery R&D capacities in China

The Chinese battery cell manufacturer Eve Energy, whose customers include BMW, has opened a large research and development centre in Huizhou in the Chinese province of Guangdong for 2 billion yuan – the equivalent of around 274 million euros.

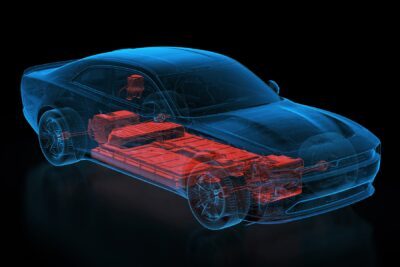

According to the manufacturer, the 145,000-square-metre centre was built within 16 months. It houses the company’s Power Battery Research Institute and Battery System Research Institute, as well as electrical performance and safety testing centres and R&D labs. Eve Energy says it plans to use the facility primarily for precision testing and analysis of cylindrical and prismatic cells, as well as battery management and energy storage systems.

Eve Energy manufactures a range of battery types, but has so far specialised mainly in the development and production of LFP cells. According to Eve chairman Dr Liu Jincheng, his company is expected to complete a comprehensive R&D structure for electrochemical energy systems by the end of 2023 and “make every effort to establish itself as the world’s most innovative lithium battery company”. A number of new technologies are in focus: first and foremost, larger round cells, a new battery system, the lithium metal secondary battery, solid-state batteries, sodium-ion batteries and hydrogen solutions.

Eve Energy gives a development status for some of these innovations in its current announcement. The new-generation round cells, for example, are said to have an energy density of 350 Wh/kg and can be charged in nine minutes. The background is that Eve Energy is an industrialisation partner of the Israeli company StoreDot, which is developing extremely fast-charging battery cells with silicon-containing anodes. According to Eve Energy, the company’s own pilot line has already produced “more than half a million samples with an overall excellent quality rate of 92 %”.

In parallel, the Chinese are working on a new battery system based on CTP technology (“cell-to-pack”). According to current information, this should achieve an energy density of 260 Wh/kg with a simultaneous weight reduction of ten per cent. The use of new, highly efficient composite materials and adhesives is said to be decisive.

As for the cylindrical sodium-ion battery cell, the manufacturer cites a specific energy density of up to 135 Wh/kg and a capacity retention rate of up to 90 % at 10 °C. Eve Energy says it intends to further develop the cell with end customers before undertaking initial pilot tests.

For its current generation of cells, Eve Energy is currently expanding its production capacity in China. New plants are planned or under construction in Chengdu, Yuxi and Jingmen. In September, BMW announced that it would rely on supplies from Eve Energy (other suppliers include CATL and Envision AESC) for the round cells for the “new class” from 2025. Two plants are to be reserved for this purpose alone. BMW had commissioned Eve Energy with the construction of battery cell factories, it said in September.