Mercedes has decided on drive production system

On the way to a purely electric vehicle range by the end of the decade, Mercedes-Benz has now made important decisions for drive production. This means that it has been decided in which plants the drive units and battery systems will be assembled.

After Mercedes had determined the production order of the vehicle plants for the electric vehicle models and platforms in the summer, the component plants will now follow – for the period from 2024. “As part of the implementation of the Mercedes-Benz Business Plan”, the company says it will invest a mid-single-digit billion euro amount in its European powertrain production sites.

First, the battery network: in Germany, the plants in Kamenz in Saxony and Brühl in Swabia (as part of the Untertürkheim plant, not to be confused with Brühl near Cologne) will produce the battery systems for the new models of the MMA and MB.EA platforms. In addition, there is such an assembly plant in Beijing for the joint venture there. In this context, Mercedes speaks of “battery factories” and the “production of batteries”. However, this does not mean cell production, but the assembly of ready-to-install battery systems from purchased cells.

Another battery assembly plant is planned at the Kölleda site in Thuringia – up to now Mercedes has manufactured internal combustion engines there, among other things. However, the final decision on this is still pending – depending on the funding commitment of the Thuringian state government. A letter of intent has already been signed in which the government pledges its support. A battery recycling factory is planned at the Kuppenheim site.

Since 2021, the battery systems for the EVA-2 vehicles built in Europe – i.e. the EQS (Sindelfingen) and EQE (Bremen) – have already been assembled in the Hedelfingen plant section, which also belongs to the main Untertürkheim plant. Since 2020, battery systems have been manufactured in Jawor, Poland, in addition to combustion engines – initially for plug-in hybrids, and since 2021 also for the EQA and EQB.

Untertürkheim and Hamburg become important electric drive plants

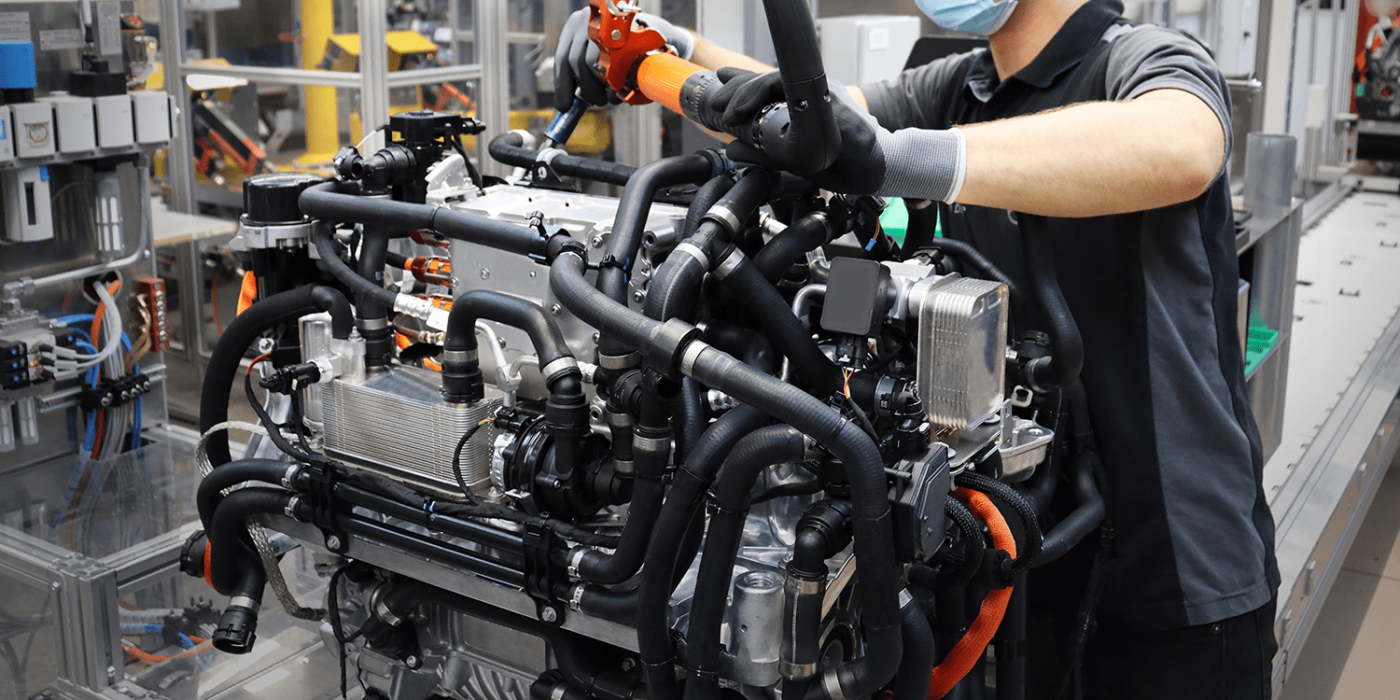

As far as drive units are concerned, it was already leaked a few days ago that production capacity at the Untertürkheim plant is to be doubled to one million units per year. Assembly is planned in the Untertürkheim and Bad Cannstatt plant sections, while parts for the drive units are to be manufactured in the Mettingen plant section from 2024. The flexible drive axle production is also located there. In addition to Untertürkheim (Untertürkheim and Bad Cannstatt plant sections), Hamburg will also be one of the “German core plants for the assembly of electric axles and components”. It has already been known since 2021 that the Berlin plant will produce high-performance electric motors for the future AMG.EA platform from the middle of the decade.

In contrast, the drive units for the MMA and MB.EA platforms will be built in Untertürkheim, in Sebes, Romania, and in Beijing. The component plant in Hamburg (including axle components and various powertrains) will also produce drive units for a model of the MB.EA platform from 2024, while the vehicle itself is to be built at the Bremen plant. Since 2019, Hamburg has been supplying the Bremen plant with electric axles for the production of the EQC – and since 2022 also for the EQE.

According to Mercedes, the new production arrangement is, among other things, “the result of constructive discussions with the German employee representatives”. In return for the billion-euro investment, “resulting in agreements to further increase flexibility and efficiency at the various locations” (as a kind of concession to the workforce and “securing the future of the plants”).

“With the new production setup, our powertrain plants are now optimally positioned for the new vehicle architectures from 2024,” says Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, Production and Supply Chain Management. “Sustainable, digital and flexible, our highly qualified and motivated colleagues around the world are now preparing for the rapid ramp-up of electric drive systems.”

Ergun Lümali, Deputy Chairman of the Supervisory Board and GBR Chairman of Mercedes-Benz Group AG, added: “In the realignment of the global production setup with regard to all-electric vehicle architectures, we demanded from the outset: The German locations must play an essential role. In the summer, we were already able to agree on visions of the future for the vehicle plants. It was always clear to us that we wanted to achieve this for the powertrain locations as well. Our persistence has paid off. I am pleased that we have created security and clear prospects for our colleagues in the powertrain production network.”

With reporting by Sebastian Schaal, Germany.

0 Comments