Mercedes to build it’s own drives from 2024

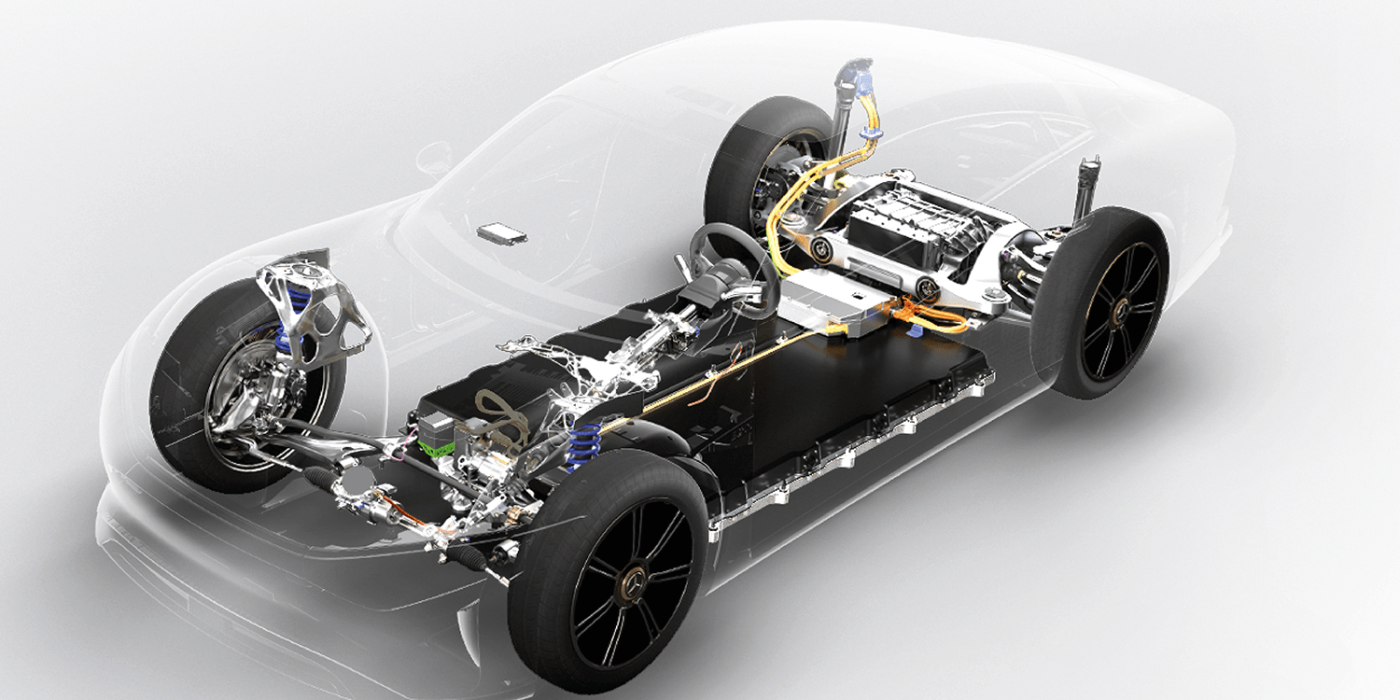

Mercedes-Benz wants to significantly increase its vertical integration for the next generation of electric cars. This is to be achieved, among other things, through in-house production of the electric drives from 2024.

As Daimler’s head of development Markus Schäfer told German media, Mercedes will build the entire drive system for the announced new electric architectures MMA and MB.EA completely in-house from 2024. “The first kit with the axial motors from Yasa for higher performance will be based in Berlin,” Schäfer said. “The second kit with Mercedes’ axial engines for the more compact vehicles will be built in Untertürkheim.”

Mercedes-Benz had already announced the production of EV components at the Berlin-Marienfelde engine plant in March 2021. At that time it was already said that it would involve the final assembly of electrical components for future compact EQ models as well as the assembly of the so-called EE compartment for the integration of power electronics for battery systems.

Mercedes has so far sourced the electric drives from external partners, primarily ZF. Among other things, the supplier has supplied the Stuttgart-based manufacturer with the complete drive module for the EQC. The electric motors for the EQS come from Valeo Siemens eAutomotive. The outsourcing of the electric drive systems with simultaneous job cuts in the company’s own plants has been a point of contention between the management and the works council time and again in the past.

However, Schäfer does not cite the capacity utilisation of the plants as the reason for the change in strategy. “We want to master the overall system of electric motor, battery and power electronics as well as possible, similar to what is the case with the combustion engine,” Schäfer is quoted as saying. As far as the inverter is concerned, Schäfer added that it has not yet been decided whether this component will be manufactured in-house.

Nevertheless, the head of development assumes that production will be expanded. “We will certainly have to discuss globally an expansion of capacity for the electric powertrain, because we are accelerating significantly in electromobility and by 2025 half of our vehicles will already be on the market purely electrically or as plug-in hybrids,” said Schäfer – naming the e-drive productions in Berlin and Untertürkheim mentioned at the beginning.

Eight battery plants planned with partners

As Schäfer now – unsurprisingly – further announces, the batteries of the vehicles will also use cells developed in-house for the first time. For the production of cells, Daimler is relying on ACC, for one thing. In addition to the factories in Douvrin, France, and in Kaiserslautern, it is assumed that there will be at least one further production facility in Germany. “We will also announce the construction of a factory for Europe with another partner in the near future,” Schäfer said.

According to information from Automobilwoche, the partner in question is the Chinese cell specialist Farasis. Farasis wanted to build a production plant for Europe in Bitterfeld, Germany, but had so far hesitated to do so. According to the report, the standstill should be over in the next few weeks.

When Mercedes presented its electrification strategy in July, there was already talk of eight cell factories to be built together with partners. However, no target year for the eight battery plants was mentioned. A “highly standardised” battery cell is to be built in the factories, which is to be installed in 90 per cent of all Mercedes models.

automobilwoche.de (in German)

0 Comments