British Lithium extracts lithium from granite in Cornwall

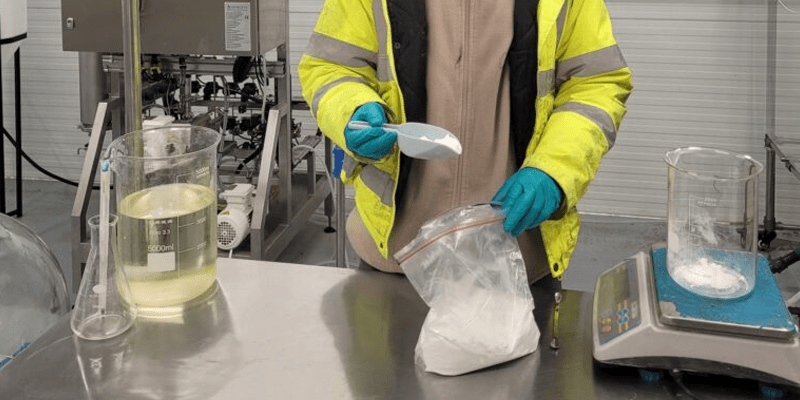

The company British Lithium says it has extracted lithium from granite for the first time – initially on a pilot scale. The pilot plant is expected to produce five kilogrammes of lithium carbonate per day from the beginning of this year.

That is enough to prove to potential customers that the technology works, British Lithium says. For the extraction, the company uses an old clay pit in Cornwall, where the lithium is embedded in granite.

However, the lithium content in the granite is probably relatively low. In Australia, where lithium is also extracted by conventional mining, the lithium content is said to be four times as high. In order to still be competitive in terms of costs, British Lithium has developed what it claims is a particularly efficient process to process the raw material. The process is said to work at lower temperatures, which saves energy. The use of chemicals was also reduced.

Specifically, the ore-bearing granite is crushed and ground. This is followed by the newly developed calcination at lower temperatures, before the lithium carbonate is leached acid-free and purified in several steps.

British Lithium CEO Andrew Smith said they were pleased with the rapid progress they had made with the process. “We’re delighted with the rapid progress we’ve made, but there’s still a long road ahead in terms of refining and optimising the process,” Smith said. It took seven months to design and build the pilot plant, however, the company has been working on the process for four years.

According to Smith, the pilot plant on site is important. “Doing it now allows us to operate in real-world conditions using actual site water and locally sourced commercial reagents. We’re delighted with the rapid progress we’ve made, but there’s still a long road ahead in terms of refining and optimising the process,” says the CEO. “New processes are normally piloted during the definitive feasibility stage but, as lithium has never been produced commercially from mica before, de-risking our proprietary technology is an important step in developing our project.”

Looking ahead, British Lithium plans to build a large plant to produce 21,000 tonnes of battery-grade lithium carbonate per year. This plant is to be built in close proximity to the granite quarry. On the one hand, to keep the transport routes short, on the other hand, to create jobs in the region of Cornwall.

1 Comment