Blackstone begins series production of 3D-printed battery cells

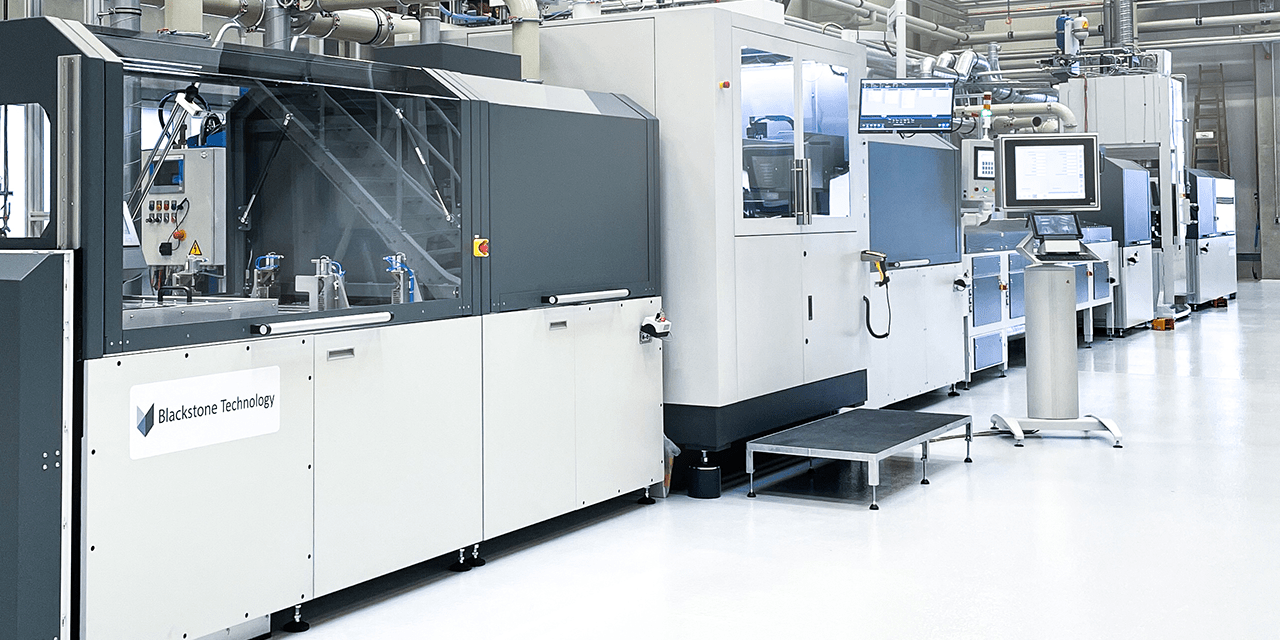

Blackstone Resources presented its manufacturing process for lithium-ion batteries from the 3D printer at an event at its plant in Döbeln, Saxony. The facility for series production was also started up as part of the event.

The event and production take place at Blackstone Technology, the German subsidiary of the Swiss holding company Blackstone Resources AG. Due to the Corona situation, however, the press conference had to be broadcast online.

Blackstone presented its LFP cells, announced in February, in detail. Using the cathode material from IBU-Tec in Weimar, the LFP cells are now being produced in Döbeln in the district of Central Saxony using a new 3D printing process. According to the company, this allows the power storage layers of the battery cells to become thicker, which should increase the energy density by 20 per cent – Blackstone calls this “Thick Layer Technology”. Specifically, Blackstone announced 220 Wh/kg. By comparison, the blade batteries of the Chinese manufacturer BYD, which are considered technologically advanced LFP cells, are said to come to 166 Wh/kg at the cell level.

Blackstone further states that the size of the cells can be flexibly tailored to customer requirements with the process – a carmaker with a battery pack installed in the underbody has different requirements here than the manufacturer of an electric bus who mounts the batteries on the vehicle roof. Blackstone puts the space savings at 15 per cent, the material savings at 20 euros/kWh. And the energy consumption in production is 23 per cent lower. Although Blackstone is starting with LFP and NMC cells, the technology should be applicable to all cell chemistries. Blackstone also wants to be able to print solid-state batteries – with solid-state technology, the energy density should then increase by another 70 per cent.

Battery cells by the second

Ulrich Ernst, founder and CEO of Blackstone Resources, calls the 3D-printed batteries a “game changer”. “It allows us to achieve a 20 per cent increase in the energy density of our charge carriers while drastically reducing environmentally relevant impacts,” says Ernst. “The patented process relies on an environmentally friendly, purely water-based process and reduces waste materials by 50 per cent. In this way, we are making an important and sustainable contribution to the transport turnaround and in the fight against climate change.”

During the event, not only was the cell presented, but series production of the electrode was also started. The target production capacity of 500 MWh is to be reached at the site as early as next year. The long-term goal is to produce battery cells every second, says Holger Gritzka, managing director of Blackstone Technology. The vision: “With a single machine park, we print cells in different shapes, different electrodes and electrolyte materials quickly and cost-effectively on a large scale.”

Currently, 14 people are employed in Döbeln, with plans to expand to 38 employees in the coming year. The German subsidiary Blackstone Technology built the production facility in an existing building to save time. According to Gritzka, the property had not only convinced him with its suitable size and its as-new condition, but also with its location: cities such as Leipzig, Chemnitz and Dresden are all quite similarly distant, which should simplify the search for qualified employees.

Incidentally, the fact that the production start announced in February could not be kept in the summer was not due to the employees – but unsurprisingly to the Corona pandemic: the production plant could only be completed after a three-month delay due to delivery problems and restrictions.

Not only Blackstone representatives appeared at the virtual event, but also partners such as Robert Orten from Orten Electric Trucks, Thomas Sautter from Voith, Benjamin Friedirch from Ecovolta and Michael Roscher from Liovolt. “The next step is now to develop a battery system with our partner ecovolta, and with Voith SE and Orten Electric Trucks we are aiming for a project to equip electrified e-buses with our battery technology,” says Serhat Yilmaz, CMO at Blackstone Resources.

Expansion plans inside Germany and around the world

In addition, Blackstone is already working with its partner Liovolt on a further development; a bipolar battery. These are lithium-ion batteries consisting of stacked electrodes connected in series, which are designed to be bipolar. “This means that the active materials for the cathode and, on the other side, the active materials for the anode are placed on a common electrode carrier,” Yilmaz explains.

In perspective, production is to be expanded beyond the 500 MWh of Phase I: In his presentation, Gritzka also spoke of small-scale production. The second phase will have a capacity of five GWh per year and will also be built in Germany. Then, in addition to pouch cells, prismatic cells are also to be produced. Phase III, an automotive cell with “10+ GWh/year”, is to be implemented through an expansion in Germany and a worldwide expansion. However, Gritzka did not give a timetable for phases II and III.

Source: Press release via email

Reporting by Sebastian Schaal, Germany.

1 Comment