Bosch launches semiconductor production in Germany

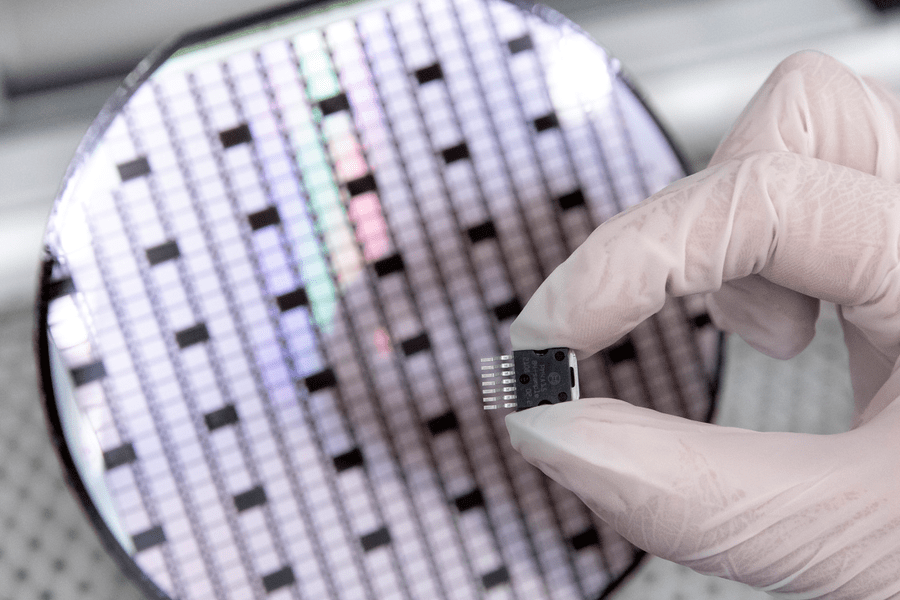

After several years of development, Bosch in Reutlingen has now started large-scale production of power semiconductors made of silicon carbide (SiC). In parallel, however, the further development of the semiconductors and the expansion of production capacities are already underway.

The start of production of SiC semiconductors is not a reaction to the current chip shortage, but is due to the trend towards electromobility: Semiconductors based on silicon carbide are more efficient than those made from other sulitium substrates. If they are installed in the power electronics of an electric drive system, for example, the higher semiconductor efficiency increases the range of the electric vehicle without having to install a larger battery. In addition, faster charging processes become possible.

Two years ago, Bosch had already announced that it would enter the production of SiC chips and push ahead with their development – until now, Bosch has manufactured more conventional silicon semiconductors in Reutlingen. “The future for silicon carbide semiconductors is bright. We want to become a global leader in the production of SiC chips for electromobility,” says Harald Kröger, member of the board of management of Robert Bosch GmbH.

The SiC chips produced in the “highly complex” manufacturing processes developed in-house have already been manufactured since the beginning of the year as samples for testing and validation by customers. The supplier does not have to worry about sales of the series production that is now starting. “Our order books are full, thanks to the boom in electromobility,” says Kröger.

For this reason, further expansion of capacities is already planned: In the future, Bosch says it wants to increase the production capacity of SiC power semiconductors to a number of units in the three-digit million range. This will apparently take place primarily at the Reutlingen site, where the cleanroom area is already being expanded, according to the statement. Already in the course of 2021, 1,000 square metres have been added, and by the end of 2023 the Bosch Waferfab is to be expanded by a further 3,000 square metres.

Bosch opened its new semiconductor factory in Dresden in the summer. Although chips for the automotive industry, among others, are produced there based on 300-millimetre wafers (instead of the 150- or 200-millimetre wafers from Reutlingen), these are not based on silicon carbide.

A brief digression on the importance of SiC semiconductors compared to silicon chips: SiC semiconductors have a higher conductivity and enable higher switching frequencies compared to silicon chips. In addition, only half as much energy is lost in the form of heat, which increases the range of electric cars. Since less heat is emitted and the SiC components can also be operated at higher temperatures, the cooling system of the power electronics can be smaller. This not only saves energy directly, but can also reduce weight and costs thanks to the more compact cooling systems.

In addition to expanding production capacity, the semiconductors themselves are also being further developed. Bosch wants to have developed the second generation of SiC chips ready for series production as early as 2022, which should further increase efficiency. The development work is being funded by the German Federal Ministry of Economics and Technology as part of the IPCEI Microelectronics. Independently of this, Bosch is also leading the establishment of a European SiC supply chain as part of the ‘Transform’ project.

In the case of SiC semiconductors, Bosch plans to manufacture the chips on 200-millimetre wafers. Since 150-millimetre wafers have been the norm for SiC semiconductors up to now, the aim is to achieve “important economies of scale that should not be underestimated”. The logic is simple: it takes several months for a wafer to go through the several hundred process steps. “By producing on larger wafers, we can manufacture significantly more chips in one production run and thus supply more customers,” says Kröger.

With reporting by Sebastian Schaal, Germany.

1 Comment