IAV presents modular light BEV platform

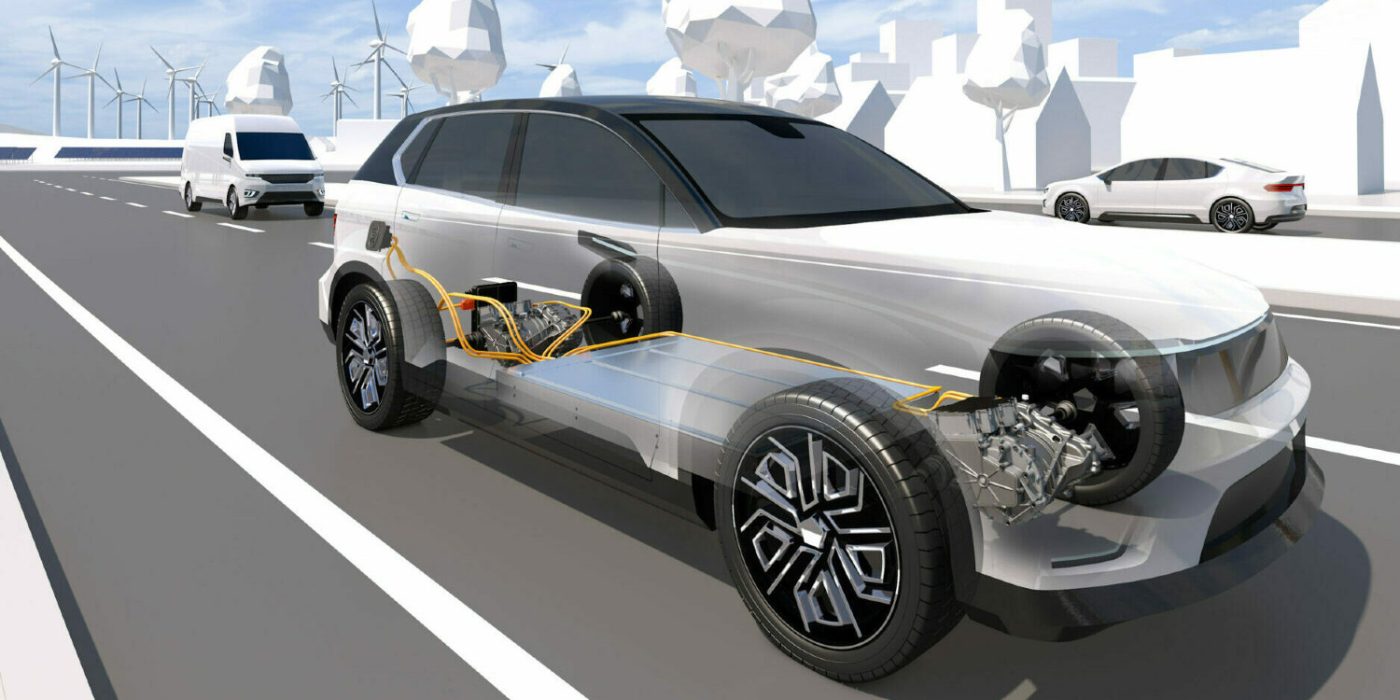

Berlin-based engineering service provider IAV has presented a modular platform for battery-electric vehicles that supports construction from small cars to light commercial vehicles. The electric modular system is supposed to make the development of BEVs “faster, cheaper and more sustainable”.

The platform developed by the Berlin-based company covers a power range from 100 to 440 kW, battery capacities from 27 to 115 kWh and voltage levels of 400 and 800 volts. It also enables the use of both silicon (Si) and silicon carbide (SiC) in the power electronics. According to IAV, the flat e-drive train platform will offer a wide range of variants for all vehicle segments and their drive topologies. As an example, the company cites the choice between front, rear or all-wheel drive and optional additional functions such as torque vectoring to increase driving dynamics.

In total, IAV says it has virtually generated and evaluated around 24 million technically feasible powertrain variants. According to the company’s headquarters, simulation tools were used to systematically vary and combine the main systems of battery, electric motor, inverter and transmission. The result: “With the modular E-kit, we cover the requirements of the entire fleet we defined. We can also vary from low-cost solution to high-performance version in vehicle classes, for example, in the SUV,” explains Rene Kockisch, team leader System Development Mechanics at IAV.

In the following video, IAV specifically shows five platform types: A 400-volt front-wheel-drive variant for small cars with 27 to 42 kWh battery capacity, 100 to 130 kW power and 2,000 to 2,800 Nm. The next larger platform with 400 or 800 volts and rear- or all-wheel drive, offering 42 to 70 kWh, 100 to 300 kW and 2,800 to 5,600 Nm. Another mid-size platform – also with 400 or 800 volts and rear- or all-wheel drive, but with 62 to 70 kWh battery capacity, 130 to 370 kW and 2,800 to 6,950 Nm.

These are joined by two larger 800-volt variants of the platform, each with 70 to 115 kWh. While the former comes as either an all-wheel or rear-wheel-drive model with 150 to 440 kW and 3,500 to 8,300 Nm, the latter is designed as an all-wheel or front-wheel-drive model with 150 to 300 kW and 3,500 to 6,950 kW.

In addition to flexibility, IAV’s EV platform is said to be particularly convincing in terms of sustainability. The Berlin-based company claims to have developed a special eco-design based on a life cycle analysis for battery selection, specifically an “extremely resource-saving solution that contributes to the fact that less CO2 are emitted in battery production through better material selection, connection technology, disassembly and recycling than in the production of conventional power stores”.

Erik Schneider, Head of E-Traction & Hybrid Drivetrain at IAV, describes platforms as the key to mastering variant diversity and to reducing development time and, in particular, product costs through economies of scale. In addition, “Affordability and sustainability are two of the biggest challenges for e-mobility. The consistent implementation of platforms in eco-design can make e-mobility more affordable and sustainable.”

IAV is already using the electric drivetrain platform in various projects with customers requiring either subsystems or complete electric drivetrain solutions. The company employs more than 8,000 people worldwide and counts among its customers, according to its own statements, “all well-known automobile manufacturers and suppliers”. In addition to traditional vehicle and powertrain development, IAV has now also established a broad base in the fields of electromobility and autonomous driving. In addition to its development centres in Berlin, Gifhorn and Chemnitz/Stollberg, IAV has further locations in Germany, including Munich, Sindelfingen and Ingolstadt. Only recently, the service provider announced its intention to build a new development centre near Stuttgart.

0 Comments