BMW invests in new lithium mining process

BMW i Ventures has invested in the US start-up Lilac Solutions. Lilac has developed an innovative process for the environmentally friendly and resource-saving mining of lithium. With the investment, the BMW Group wants to promote “technological progress in the field of lithium mining”.

The US start-up has developed and patented a technology that uses an ion exchanger to significantly improve the mining of lithium from the brine of saltwater deposits in terms of efficiency, costs and sustainability. According to BMW, the technology has already proven itself in initial field projects. It must now prove “that it is scalable and can be industrialised in the medium term”.

The great hope is that the process will be designed in such a way that it can be used worldwide in brines, even if they only have a low lithium content. In previous processes for extracting lithium from brine, the moisture is gradually removed from the brine until the solids remain and can be further processed. The evaporation takes place either in large evaporation basins or underneath in special plants, which, however, require further energy.

BMW states that the investment is focused on responsible and sustainable extraction. “Innovative technologies provide better, more sustainable and more efficient access to raw materials,” says Wolfgang Obermaier, Head of Indirect Goods and Services, Raw Materials, Production Partners of the BMW Group. “By investing in startups, we are speeding up development of new technologies, stimulating competition and providing impetus that will make it easier for young companies to access the market.”

BMW does not provide details on the financial scope of the investment in Lilac Solutions in the statement. A concrete timetable or the planned development steps are also not mentioned.

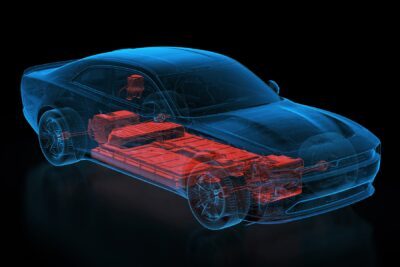

The BMW Group, including the vehicles of the BMW, Mini and Rolls-Royce subsidiaries, aims to achieve at least half of its global sales with fully electric vehicles by 2030. Vehicles. “Accordingly, the demand for lithium, an important raw material for the production of battery cells, is increasing,” BMW writes. For critical raw materials such as lithium, BMW has developed a special supply chain: The carmaker buys such materials itself directly from raw material producers and makes them available to its own suppliers (in this case battery cell manufacturers) for the production of BMW cells. In this way, the Munich-based company aims to create “complete transparency about the origin and mining methods of the material”.

0 Comments