Mahle presents new immersion battery cooling system

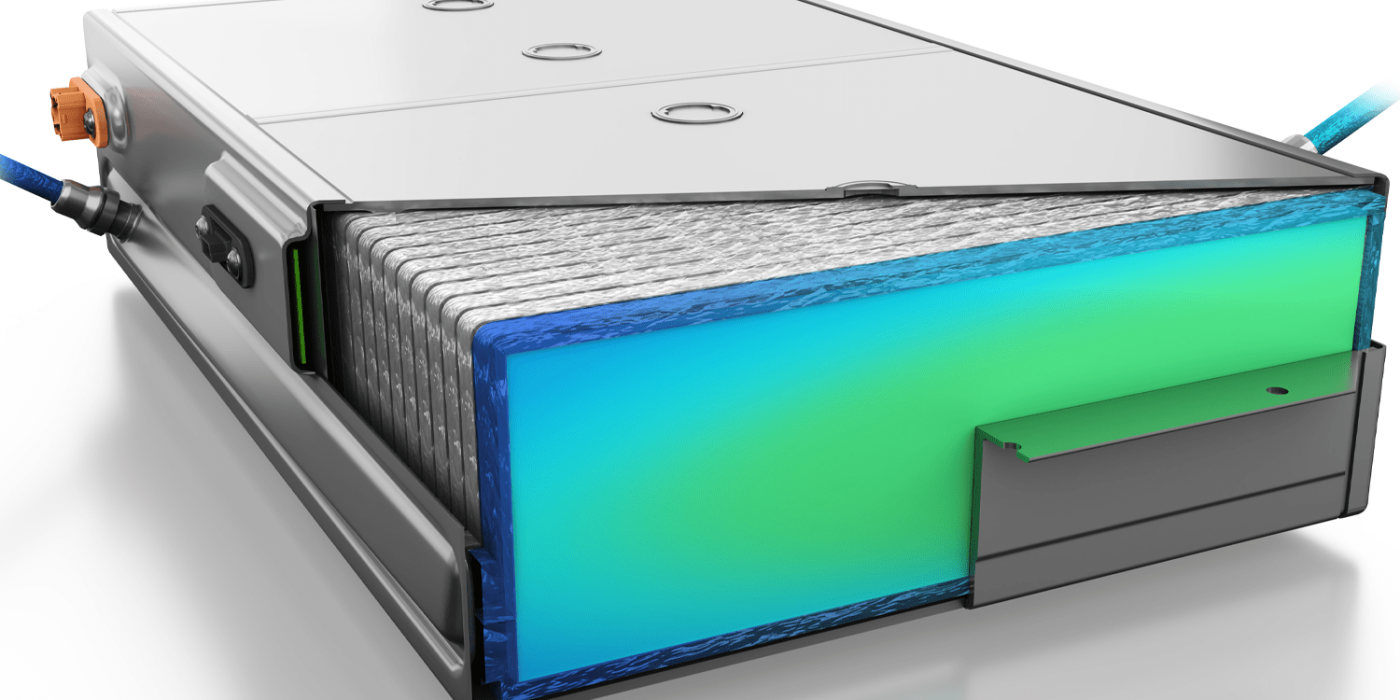

Mahle has developed a new type of battery cooling that the company says will enable faster charging of electric cars. The automotive supplier is relying on immersion cooling as a key technology.

As the name “immersion cooling” suggests, here the battery cells are directly washed by the non-conductive coolant – in contrast to the currently dominant systems for battery cooling, in which the coolant flows through special channels or plates between the cells. According to Mahle, this should enable the maximum temperature of the battery to be significantly reduced during charging and the “temperature to be distributed much more homogeneously overall”.

Mahle does not yet want to specify exactly how much the temperature can be lowered in this way and what other requirements are placed on the battery for immersion cooling, even when asked. A spokesperson told electrive that the only other advantages are that the ageing of the cells is less and that the battery offers more safety in the event of damage – again, without giving further details. However, the cooling solution is said to be designed in such a way that charging outputs of up to 750 kW should be possible in relation to the chargeBIG Power charging solution also presented at the IAA.

“Immersion cooling paves the way for a whole new generation of battery systems,” says Martin Berger, Head of Group Research and Advance Engineering at Mahle. In July 2020, the supplier had presented a new cooling capacitor that is also optimised for fast charging of electric vehicles. The capacitor is “powerful enough” to be combined with the new cooling system, the spokesperson said.

Mahle says it intends to use its know-how in the field of electromobility, covering thermal management, plastics and power electronics, to develop new, integrated solutions for e-vehicles. The focus is on the areas “where e-mobility still needs a boost” – specifically, Mahle mentions charging speed, range, resource conservation and price.

0 Comments