ZF presents modular electric drive kit

At the IAA Mobility, the supplier ZF presented a new electric drive kit called Modular eDrive Kit. The kit is designed to continue offering customer-specific solutions – but in half the usual development time.

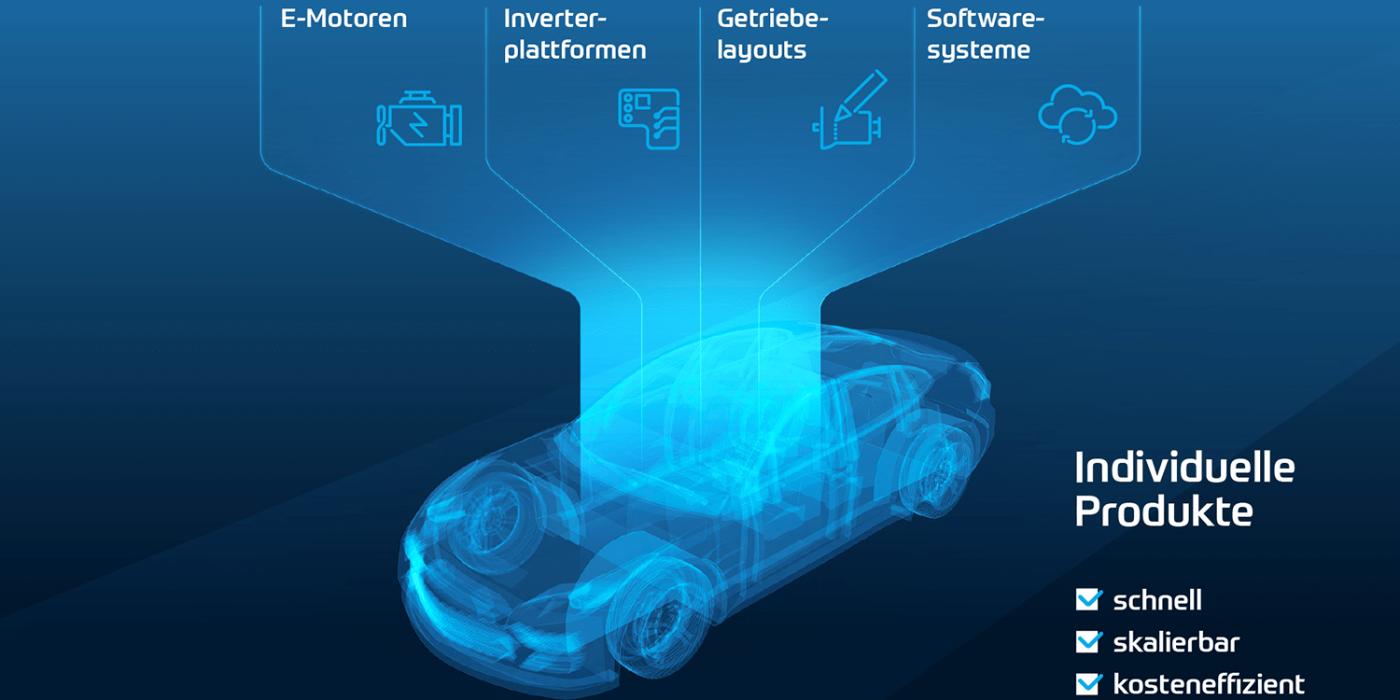

The ZF kit includes electric motors, an inverter platform, various transmission layouts and software systems. In concrete terms, the drives are to cover the power range from 75 to 400 kW with a torque between 350 and 540 Nm – depending on the customer’s requirements with a focus on maximum performance, costs or efficiency.

As an example, ZF cites a compact car with a 100 kW drive and a 400-volt inverter. Still, a premium model with 200 kW drive power and 800-volt inverter based on silicon carbide is also possible – “depending on whether the focus is on cost efficiency or technological leadership”.

ZF cites the shorter development times as a major advantage. In addition, since system design, construction, software, electric motor concept, cooling and some components are developed across platforms, “synergy effects and a higher degree of maturity arise right from the start”, says the supplier from Lake Constance.

On 400-volt technology, the drives are to be in the “Low” and “Mid” versions. “Low” covers the range below 100 kW, “Mid” offers drive solutions up to 200 kW. According to ZF, both are based on ASM or PSM machines. The “High” drive solution is an 800-volt drive with the silicon carbide inverter mentioned above. The PSM here has an output of over 200 kW. “All new drives bring significant improvements in power density, weight and efficiency,” says Otmar Scharrer, responsible for the development of electric drives at ZF.

In addition to the “Modular eDrive Kit”, ZF offers the “eConnect” module for all-wheel drives. According to the press release, the system is designed to make it possible to uncouple the second axle to reduce mechanical drag losses by up to 90 per cent. If the second drive is needed, it should be engaged “within milliseconds via a claw clutch without losses”. ZF expects an increase in efficiency “of significantly more than two per cent compared to the best comparative system currently on the market”.

0 Comments