Bosch offers battery factory starter set

Bosch has announced that it will now offer its customers factory equipment for battery production from a single source – from individual components to software solutions to complete assembly lines. The first customer has already been found.

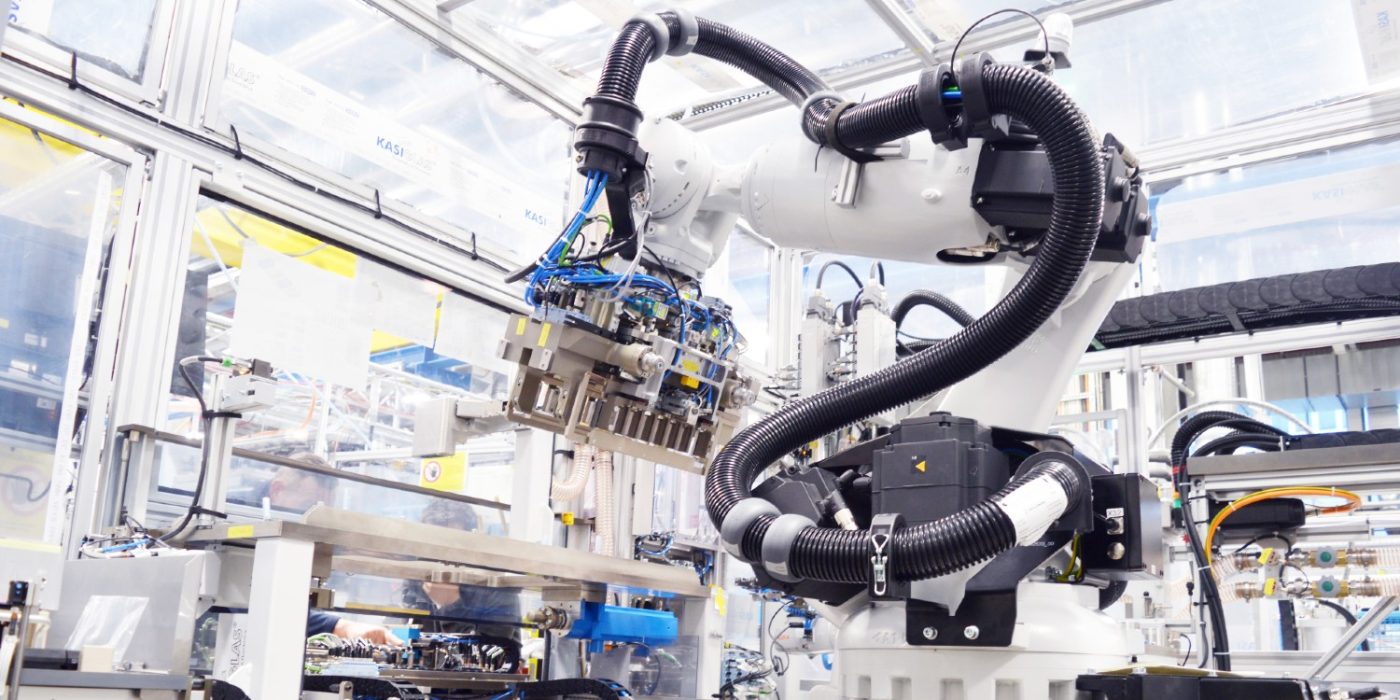

According to Bosch, the supplier Webasto will equip battery factories with Bosch technology. Bosch will supply automated assembly lines for welding and gluing the battery cells. “Robots automatically assemble the cell stacks in a two-step procedure consisting of dispensing technology and laser welding. With a comprehensive safety concept, it is then possible to establish the battery module’s electrical connection using a highly dynamic and precise laser-welding process,” Bosch describes the process.

But Bosch also wants to use the technology itself: At the Eisenach site, where Bosch assembles 48-volt batteries for hybrid cars from purchased cells, the company plans to invest 70 million euros in expanding production.

“We know batteries like the back of our hand, as well as how they have to be manufactured,” says Bosch board of management member Rolf Najork, who is responsible for industrial technology. “Our assumption is that the global battery market will grow up to 25 percent each year. Bosch is doing its part to meet this demand.”

By entering the business field, Bosch aims to increase the depth of value added in mechanical engineering and generate some 250 million euros in sales annually from 2025 onwards with equipment for battery production. The plants will be able to produce modules and packs from ylindrical, prismatic or pouch cells – either partially or fully automated, depending on requirements.

The company is not only targeting carmakers and their suppliers as customers, but also the booming e-bike industry, for example. Bosch itself has been manufacturing batteries for e-bikes in Miskolc, Hungary, since 2015.

0 Comments