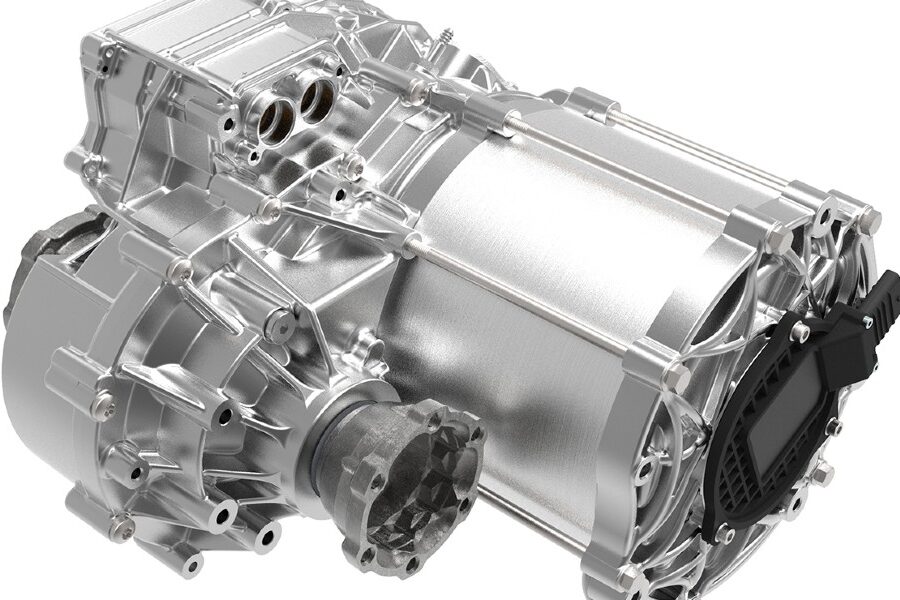

Vitesco presents new electric axle generation

Vitesco Technologies has presented the new generation of its electric axle drive. The manufacturer promises that the EMR4 is 25 per cent lighter with the same performance – and can cover a wider performance range at lower cost. The EMR4 is being built in China, among other places.

Vitesco celebrated the world premiere of the drive in China: The 13th Transmission Symposium China is currently taking place in Shanghai, during which Vitesco presented the drive solution.

Like its predecessors, the EMR4 (Electronics Motor Reducer) is designed as a drive platform: According to Vitesco, the power spectrum from 80 to 230 kW can be covered, depending on customer requirements. As a further development of the EMR3, which is used in over 20 models, the new axle drive is said to have been improved in all areas. Vitesco promises “a high power density and compact dimensions with low weight”.

Thanks to the development and industrialisation experience with the EMR3 and its predecessors, the platform has “a very high level of integration, it is modularised, scalable and standardised”.

“The key to supporting this megatrend lies in high efficiency and reliability as well as affordability for high-performing electric drive systems,” says Thomas Stierle, head of the Electrification Technology business unit at Vitesco Technologies. “We have anticipated this with the EMR4 design.” Stierle says the platform “will meet and exceed the requirements of vehicle manufacturers around the world”.

Gunter Mühlberg, head of axle drive product management, highlights scalability as an important market requirement in addition to efficiency. The new generation delivers up to 5 per cent more axle drive efficiency, much greater scalability between 80 kW and 230 kW, and “significant cost advantages”. “This is the result of consistent system optimization on detail level within numerous effect chains in the axle drive,” says Mühlberg. By comparison, the EMR3 could only cover the power range from 120 to 150 kW.

The cost advantages arise, among other things, from the fact that all variants of the EMR4 can be produced on one production line. According to Changsong Yu, head of Electrification Technology in Asia, one of the EMR4’s production facilities will be in Tianjin, China. “The EMR4 will be manufactured in China among other places, based on a local network of supplying partners,” the manager said. From the plant, “both local and international car manufacturers” will be supplied with the EMR4 – but Vitesco does not name customers in the announcement.

0 Comments