Leclanché announces new lithium battery module

Swiss battery manufacturer Leclanché has developed a new generation of lithium-ion modules for energy-intensive electrified transport applications on road, rail and water, while inaugurating a new production line for large-scale module manufacturing in Switzerland.

According to Leclanché, the new modules, called M3, have a higher energy and power density compared to the previous generation and feature a long lifetime of up to 20,000 cycles with lithium titanate chemistry (LTO) or up to 8,000 cycles with graphite/nickel manganese cobalt oxide chemistry (G/NMC). The new modules are rated for up to 800 A continuous current up to 1,200 volts and are designed “to allow a high degree of flexibility in product configurations while ensuring production efficiency and traceability,” according to Leclanché.

The Swiss company designed the M3 module for vehicles that require a high cycle life, such as commercial vehicles, railway and marine applications. Leclanché sees the higher-density G/NMC version primarily in transport applications, and the LTO version where fast intermediate reloads are required, “such as in certain bus and AGV (Automated Guided Vehicles) applications and in hybrid hydrogen fuel cell systems used in certain trucks and trains”, according to the company.

The new module is compatible with the entire range of Leclanché cells – LTO 34Ah, G/NMC 60Ah and G/NMC 65Ah. The company had only presented the latter in April. It is manufactured at the German site in Willstätt. Compared to the company’s 60 Ah cell, it is supposed to deliver ten per cent more energy and a ten per cent higher energy density (up to 515 Wh/l) – with the same size and weight.

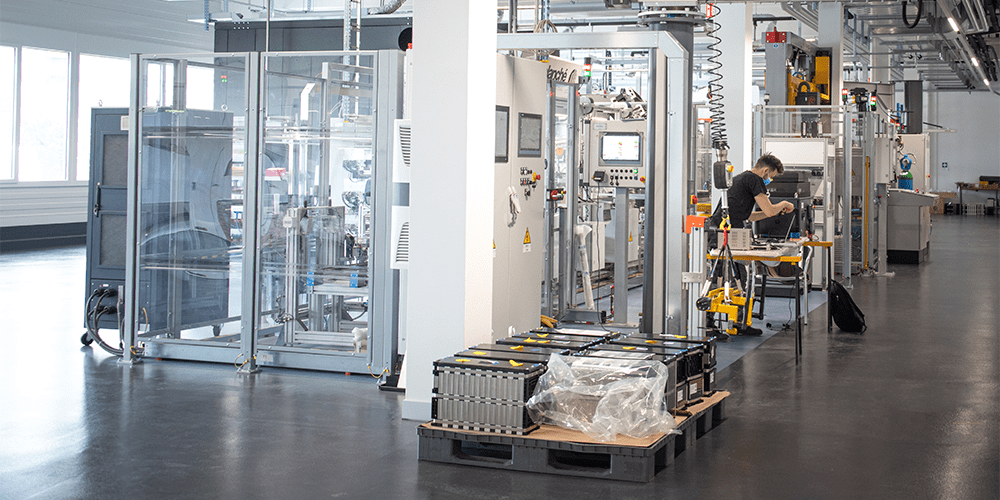

In addition to the M3 module, Leclanché announced the commissioning of a new module series production line in a new facility near its current headquarters in Yverdon-Les-Bains. It will have a production capacity of up to 500 MWh per year, increasing the current capacity by a factor of six. When fully operational, the line is expected to achieve an output of more than 60,000 modules per year, the company says. In the fourth quarter of 2021, the manufacturer plans to move its headquarters to the same building.

According to Leclanché, the highly automated production line is the result of a cooperation with Comau Spa, a provider of industrial automation and robotic systems based in Turin, Italy, which belongs to the Stellantis Group. The line is designed so that its capacity is expandable, stresses the manufacturer, which describes itself as one of the few companies producing both cells and modules on a large scale in Europe.

“Today’s twin milestone is the result of long-term planning, research and development and significant investments enabled by our employees, business partners and stakeholders,” said Anil Srivastava, CEO of Leclanché. “We are especially grateful to our clients and business partners who have collaborated with us and pushed us to innovate and deliver this next generation of battery technology which will contribute to the transformation of transportation and energy efficiency, driving the reduction in greenhouse gas emissions.”

Last summer, the Swiss-listed battery maker publicised a partnership with Eneris Group, which operates out of Poland, while strategically repositioning itself. Among other things, the partners launched two production joint ventures, one in Germany for the production of cells and the other in Switzerland and Poland for the assembly of modules. A third was also considered for France in the summer. Basically, Leclanché is organised into three business units: stationary storage solutions, e-transport solutions and dedicated battery systems.

With reporting by Cora Werwitzke, France.

0 Comments