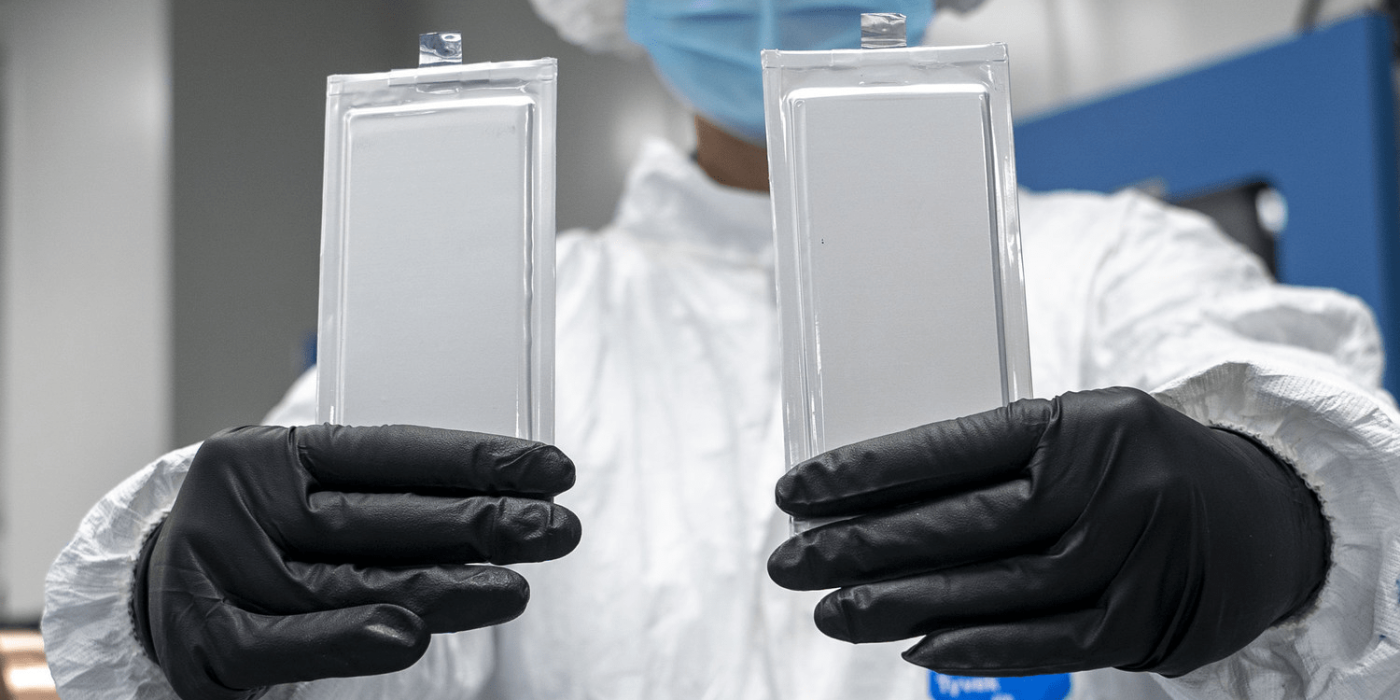

Solid Power presents details to their solid-state battery platform

US battery specialist Solid Power has released more details on its solid-state battery platform, which enables three different battery designs. It is promised that the costs for the active cathode material can be reduced by up to 90 per cent.

Unlike previously known, Solid Power’s development is not just a solid-state cell, but a technology platform. The sulphide-based solid electrolyte can be combined with anodes that rely either on lithium metal or a high silicon content. Industry-standard and commercially mature cathodes are used for this, including lithium-nickel-manganese-cobalt oxide (NMC).

In other words, current NMC-811 cathodes can also be used in this way. In combination with a silicon anode and a solid electrolyte, Solid Power wants to be able to build a cell that should have a gravimetric energy density of 390 Wh/kg. The portal InsideEVs writes of an improvement of 50 per cent compared to the 2170 round cell from Tesla/Panasonic, which is currently regarded as the market leader and which is said to achieve 260 Wh/kg.

If a lithium metal anode is installed instead of the silicon anode, the cell (still with NCM-811 cathode) comes to an energy density of 440 Wh/kg, i.e. 69 per cent more than the round cell known from the Model 3 and Model Y.

Based on this data, Solid Power has extrapolated a 77-kWh pack; the size that is used in the Volkswagen Group’s MEB models and roughly also in the long-range models of the two smaller Tesla series. Such a battery would not only be 44 per cent smaller (184 instead of 329 litres), but also significantly lighter: 304 kilograms with a silicon anode and 269 kilograms with a lithium metal anode instead of the 499 kilograms with current lithium-ion technology. The range would improve by 14 to 16 per cent, and the fast-charging capability would correspond to today’s values. The costs would also be different: instead of 10,934 dollars for the current battery, Solid Power expects 6,545 dollars for its own development.

More would probably be possible: Solid Power’s platform should also be able to use “low-cost cathode types with high specific energy conversion” that are not suitable for lithium-ion or other liquid-based cell architectures. Combined with a lithium metal anode, the cathode could be completely free of cobalt and nickel, which would reduce the cost of active cathode materials by 90 per cent. However, Solid Power did not include this technology in the 77 kWh model calculation.

Series production to start in 2026

The different approaches Solid Power is taking are to meet the “performance requirements of multiple automakers”, as co-founder and CEO Doug Campbell indicates. “Solid Power’s all-solid-state platform technology allows us to produce unique batteries for the unique electric vehicles they intend to power,” Campbell said. “The company’s roadmap now includes three battery cell designs that could power multiple electric vehicle product life cycles.”

While the recently announced investment from BMW and Ford stated that first cells with 20 Ah silicon anode cells would be manufactured in late 2021 (with 100 Ah to follow in 2022), the company now gives a year for volume production. The “high-content silicon anode product” is to be commercialised by 2026, the lithium metal anode product “will follow”. No date is given for the cobalt- and nickel-free cell.

With a start of series production in 2026, however, the comparative calculation with the 77-kWh pack must also be seen in a different light: The current technology with liquid electrolyte is also being further developed; moreover, solid-power development would continue to depend on the world market for nickel, cobalt and other battery materials for cost calculations.

“Silicon has been an area of development for Solid Power for several years and is expected to be the first anode variant to be integrated into electric vehicles,” says Josh Buettner-Garrett, chief technology officer at Solid Power. “Rather than using carbon in the anode with silicon as an additive, Solid Power is able to use compositions with more than half silicon by weight including the weight of the solid electrolyte. This enables volumetric energy densities on par with lithium metal along with specific energy that far exceeds that of conventional lithium-ion.”

Solid Power also announced two additions to its board of directors: after BMW and Ford increased their stakes, they will each be allowed to provide a board member in future. Ted Miller will join the board on behalf of Ford, BMW will delegate Rainer Feurer.

insideevs.com, prnewswire.com (battery platform), prnewswire.com (board members)

1 Comment