Ree to cooperate with AAM for new electric drive system

AAM will integrate electric drive units into Ree’s space-saving electric vehicle platform, focusing on reducing NVH (noise, vibration, harshness). The electric drives will be developed at AAM’s Advanced Technology and Development Center in Detroit. The prototypes are planned for late 2021.

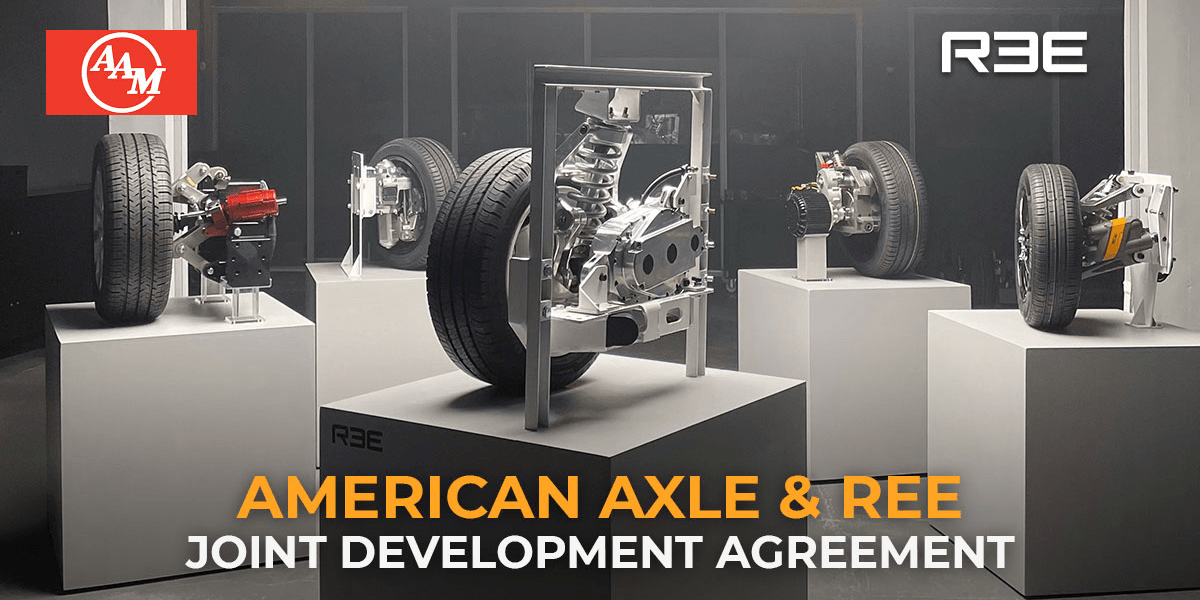

The main feature of the Ree Automotive platform is the ‘Ree Corner’, where all critical vehicle components are installed between the chassis and the wheel in the corners of the vehicle. These four compact individual modules – consisting of suspension and drivetrain – provide a flat interior floor, even between the axles. This is said to allow unprecedented space for passengers, cargo and batteries.

AAM will now develop electric drive units for this platform, including “fully integrated high-speed motors and inverter technology”. As mentioned, special emphasis will be placed on noise, vibration and harshness (NVH) reduction. This is an area where Ree’s compact drive units are likely to behave differently from a centrally placed axle motor suspended in a subframe and decoupled from the chassis. AAM describes itself as a specialist in powertrain and metal forming technologies. The company is based in Detroit and employs about 20,000 people in 17 countries.

“We are delighted to collaborate with AAM on this groundbreaking concept,” says Daniel Barel, co-founder and CEO of Ree Automotive. “AAM’s modular drive solutions enhance our product offering with a highly compact form factor that will enable more design freedom and functionality for our future customers. Together with AAM’s extensive knowledge in automotive and their global manufacturing presence, we will be able to push the REEcorner technology even further.”

With its platform, the Israeli company wants to be able to cover various use cases. The smallest version (called P1) can weigh up to 1.8 tonnes and is intended for inner-city delivery vehicles for the last mile. The number corresponds to the respective maximum weight in tonnes for the variants P2, P4, P6 and P7. P4 is intended to enable an LCV, electric shuttle bus or SUV, P7 with a total weight of seven tonnes, a medium-duty delivery truck.

A few weeks ago, Ree Automotive entered into cooperation agreements with Toyota’s commercial vehicle subsidiary Hino Motors and the supplier and contract manufacturer Magna. Here, too, the ‘Ree Corner’ platform is to form the basis. Meanwhile, Ree wants to create the financial scope for its next growth steps by going public on the US stock exchange. To this end, Ree is merging with the SPAC company 10X Capital Venture Acquisition Corporation. The transaction is expected to be completed by the end of the first half of 2021 and provide the Israelis with a capital increase of around 500 million US dollars. This sum includes a capital increase in the form of a PIPE (“Private Investment in Public Equity”) of 300 million dollars. Investors such as Mahindra & Mahindra, Koch Strategic Platforms and Magna International participate.

Incidentally, in a press release from mid-February, Ree stated that the first customers are to be supplied with the ‘REEcorners’ in 2022. Mass production is planned for 2023. The platforms will be assembled in 15 so-called integration centres around the world. The first of these integration centres is to be opened in the USA this year. REE also aims to produce in 30 countries in the future through partners such as AAM, Mahindra and KYB.

Source: Press release via email, prnewswire.com

0 Comments