Williams & Italdesign launch their own EV platform

Williams Advanced Engineering and Italdesign have joined forces to develop a modular platform for building a wide variety of premium electric cars. This platform can be used as a basis for the creation of customised vehicles. It will be offered to both new entrants and established OEMs.

The core of the joint offer is Williams’ EVX electric car platform with a structural battery. On top of this, Italdesign will offer custom electric cars to customers with its “renowned vehicle design and turnkey development expertise”, Williams Advanced Engineering (WAE) said in the statement.

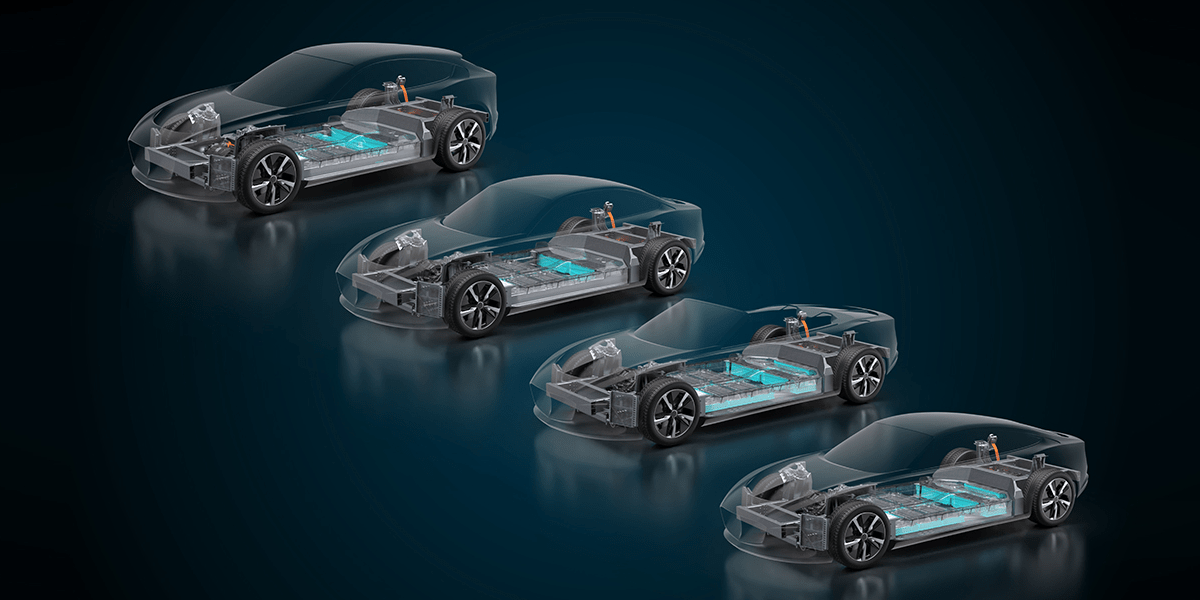

The EVX will allow electric sedans, crossovers and GT vehicles to be industrialised quickly, Williams added. In one graphic, the Brits even show a sporty electric convertible. Since the premium vehicles will not be volume models, the platform has been optimised for “performance, shorter time-to-market, flexibility and business cases for small to medium volume production”.

Customers will not only be able to choose the design and body shape, but also the powertrain. The modular battery system developed by WAE is to enable either a power output of up to 1,000 kW or a range of 1,000 kilometres, according to the statement. The British company has know-how with high-performance batteries: WAE had already developed the battery for the first generation of Formula E racing cars. While the batteries for the current Gen2 cars come from McLaren, WAE will again supply the batteries for the upcoming Gen3 cars. The batteries for the ETCR touring car racing series and the recently launched Extreme E off-road racing series also come from WAE.

The current rolling chassis is designed for battery sizes between 104 and 120 kWh. With the flexibility of the module design, up to 160 kWh per battery pack should also be possible – the latter then for the theoretically possible 1,000 kilometres between two charges.

The “structural” battery is new, which WAE emphasises as an important distinguishing feature. The battery housing is integrated into elements “that are more often perceived as part of the body structure”. “Front and rear chassis structures mount to the carbon composite case and crash loads can be transferred via internal reinforcements to the integral side sills,” Williams says. “The resulting higher profiled cross section achieves much of the torsional stiffness needed to deliver the full potential of the platform.” In doing so, the company says, there is less reliance on the “upper structure”, which should offer more freedom in the design of the vehicle itself.

Up to 10,000 vehicles possible

“Demand for high performance electric vehicles is continuing to show considerable growth but to date, there has not been a complete EV production solution,” says Paul McNamara, Technical Director at WAE. “This unique relationship brings together state-of-the-art EV rolling chassis technology with one of the world’s leaders in vehicle body engineering.”

“We aim to develop vehicle architectures in the GT, Sedan, Crossover and Convertible markets, fully customisable inside and outside,” says Antonio Casu, CTO at Italdesign. “We are targeting business cases that will cover different production volumes from an Ultra Limited Series up to 10,000 units a year, 500 of which can be built by Italdesign at our facilities in Turin.”

Williams Advanced Engineering is a development services provider that emerged from the Williams Formula One team in 2010. The Italdesign design studio has been part of the VW Group since 2010 and is assigned to Audi in the organisation.

1 Comment