BMW to launch battery production in Leipzig

The BMW Group is starting production of battery components at its Leipzig and Regensburg plants. On 3 May 2021, the series production of battery modules will start in Leipzig. The Regensburg plant already began painting battery cells for high-voltage batteries in April.

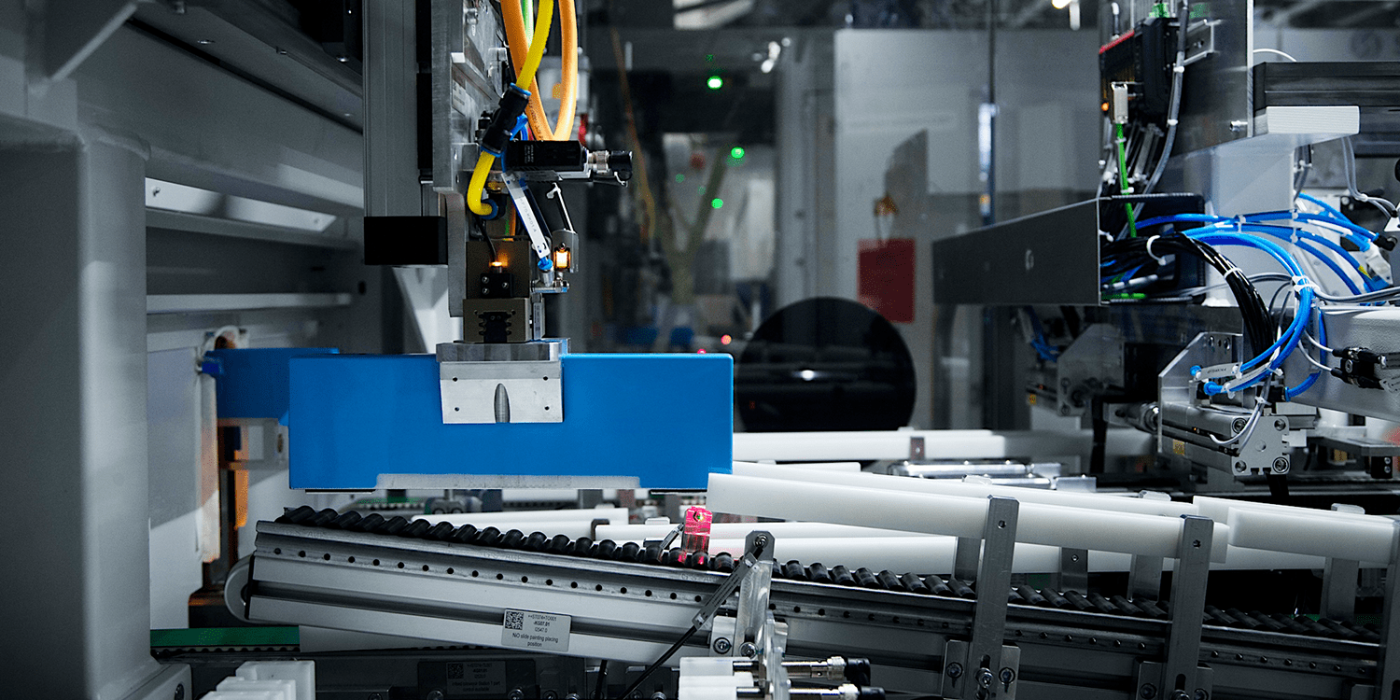

BMW had announced in September 2020 that it would be assembling battery modules in large-scale production from this year onwards with an eye towards Leipzig. Different module variants are to be able to be produced on one line. In this way, the assembly of the battery modules should not become a bottleneck if demand between different models develops differently than forecast. The module production was built on the former production areas of the i8 hybrid sports car. A second production line is to be inaugurated in 2022.

For Regensburg, BMW had announced the decision a month later, in October 2020. As the carmaker now points out, less than a year has passed in both plants since the decision to expand production capacities for e-drives and the actual start of production.

According to BMW, the painting of the cells, which has been used for a few weeks in Regensburg on the first of four planned lines, increases the mechanical robustness and thermal conductivity of the battery cell. The other three lines are to go into operation gradually by the end of 2021. From 2022, ready-to-install high-voltage batteries will then be manufactured from modules at the site.

In addition to Leipzig and Regensburg, the Dingolfing plant is also involved in the production of E-components. Modules and ready-to-install batteries are also assembled there, and the production of the electric motors is also located in Dingolfing.

The battery components are intended, among other things, for the production of the electric models BMW iX and BMW i4, both of which will be launched on the market shortly. The iX will also rely on this “fifth generation” of battery technology from BMW.

“We assume that by 2030 at least 50 per cent of the vehicles we deliver to our customers worldwide will be fully electric,” says Michael Nikolaides, Head of Planning and Production Engines and E-Drives. “Accordingly, we are consistently expanding our production network for electric drives. We are increasing capacities at existing locations and opening up others.”

BMW says it is investing a total of around 790 million euros in expanding its production capacities of drive components for electrified vehicles by 2022 – at the Dingolfing, Leipzig, Regensburg and Steyr sites. The housings for the e-drives are manufactured in Steyr. Regensburg and Leipzig account for around 250 million euros.

0 Comments