Nidec is gearing up its electric motor business in Europe

Japan’s Nidec Corporation just opened new offices in Serbia and is setting up two new factories in the city of Novi Sad. These are just part of a wider network that is to bring Nidec to the forefront of the global electric car market. This is according to this latest strategy briefing.

++ This article has been updated, please continue reading below. ++

Nidec, perhaps ambitiously, aims for “domination” in the global e-motor business within the next five years, according to CEO Shigenobu Nagamori. By 2025, the Japanese corporation then wants to supply five million electric motors to the global automotive industry and says, this would be “the line for electric cars to become the majority in the industry”. Further confirmation is expected later this April at the closing of the financial year in Japan. However, reports in November 2020 saw about one million of these motors destined for Europe, where the company is setting up additional offices and production facilities in Serbia’s Novi Sad. The city is about 90 km northwest of the capital Belgrade.

At the press event, Nidec set the start of construction for September 2021 and hopes to be at full capacity by Mid-2022. The foundation was laid in January. According to the Japanese corporation, Nidec Electric Motor Serbia’s principal business is manufacturing and selling automotive motors and related products.

Jun Seki, President and Chief Operating Officer, represented Nidec Corporation in the call following the new offices’ opening. While Nidec said they were unable to disclose specific figures, i.e. clients and capacity when asked, there was much to learn about Nidec’s rather preparatory positioning and the large scale thinking of the relatively new player, esp. when it comes to traction motors.

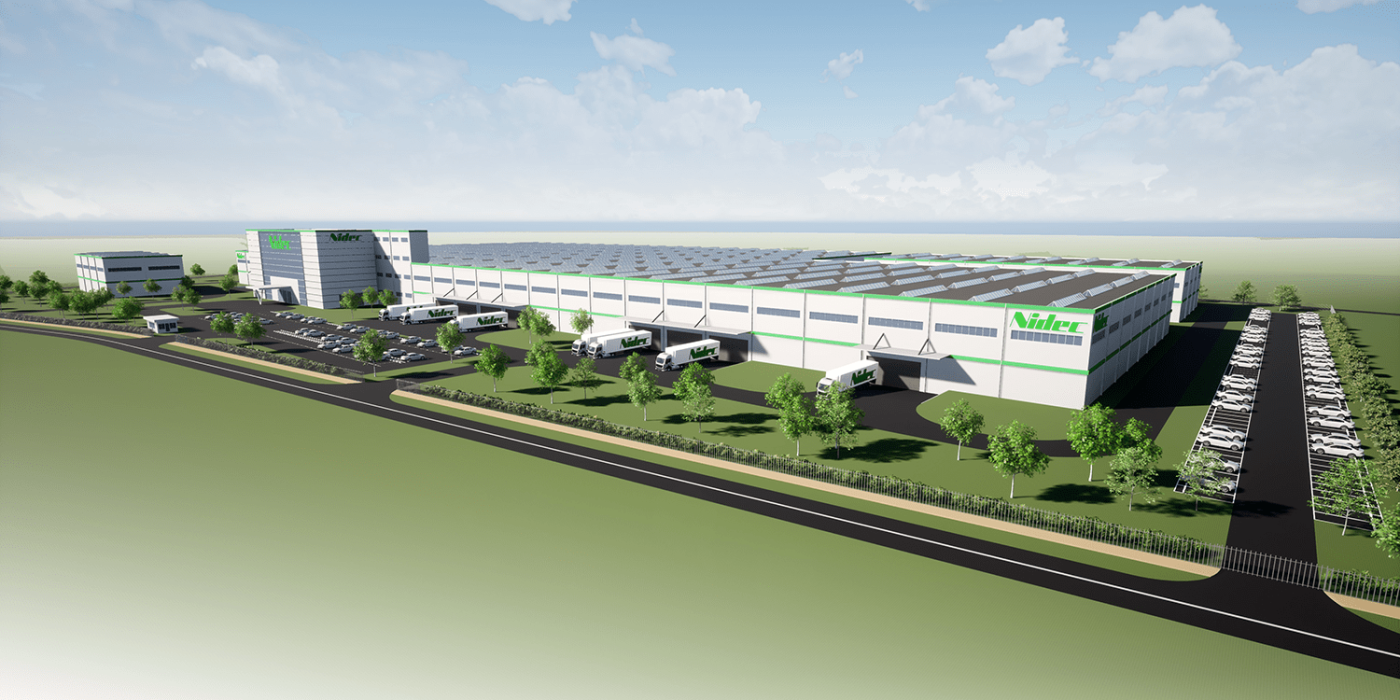

First, back to Serbia. Apart from making electric motors for automotive applications, Nidec also set up Nidec Elesys Europe LLC. The second new company signs responsible for manufacturing and sales of automotive inverters and ECUs in Novi Sad. The site will cover 36,000m2 once completed on the same schedule as the e-motor facility. Nidec intends to employ 200 people there. The e-drive business, on the other hand, will see 1,000 people work in the larger factory to measure almost 60,000m2.

When asked why Serbia, Jun Seki reasoned in line with the press statement. Nidec will recruit locally and sees a country “abundant in people in the fields of science and engineering who are fluent in English.” Apart from the available workforce, Serbia not being a member of the EU was another reason for Nidec to set up shop there. The COO reflected long-term strategic thinking, saying that being first in a market that has yet to join the European Union gave Nidec a headstart. The company also claims “tremendous support” through the Western Balkans Cooperation Initiative that the Japanese government is currently promoting in Serbia and other countries.

Upon opening the new offices, Nidec also entered into a strategic alliance with the University of Novi Sad to “actively engage in technological exchanges via industry-academia partnerships.” As an outlook, the new facilities were to consolidate the Nidec Group’s production activities in the East European region and would see Nidec’s Automotive Motor & Electronic Control Business Unit “launch multiple businesses in future.”

This is a strategy proven successful for Nidec in one of its other main markets. Mr Seki gave the example of the Kudong region in China, where Nidec set up twelve businesses, a cluster the company is beginning to mirror in Europe. The company says the new business base in Serbia would supply products to the European market while looking to design and develop products locally over time. Operating multiple firms at the same site will create synergies “by sharing the same production infrastructure and back-office,” Nidec explained. The executive added, “the beauty of this intensive area is that we can react to different demands in different segments.”

Ten billion dollars for the electric car motor business

Both the extension to China as well as the new drive for business in Europe are part of Nidec’s strategy to invest up to ten billion US dollars in the automotive segment over the next five years announced in November 2020. According to CEO Nagamori, the company intends to “dominate the market for electric vehicle engines.” In concrete figures, Nidec targets to hold a quarter of the market by 2025 and between 40 and 45 per cent by 2030.

Essentially, this is about being prepared. While traction motors are yet to become Nidec’s new business, at least in terms of scale, the Nidec COO explained that the company estimates electric cars to reach price parity with combustion or even hybrid vehicles within the next five years.

For clients, Nidec works with three different types, COO Seki explained. In China, Type A has “no problem to outsource the motor business”. Cue in Foxconn here as Nidec announced cooperation to supply electric drives for their EV platform MIH reportedly last month. Type C, however – think OEMs – insist on developing motors in-house. That is, for now, as Seki suggested, as it would be only “a matter of time” until these would come to suppliers such as Nidec, which by the time will have scaled up to be very cost-competitive. “At this moment, our opportunity is with A and B, and with C, it will take another few years until they will ask component by component or motor and inverter, and we will be ready by then,” he said.

Type B, he added, had already understood that and named Stellantis as a client. The merged business of PSA and FCA, which is expected to draw on three electric car platforms was among the few clients he disclosed without going into further detail. When asked again by electrive about actual capacities in Serbia, the headquarters in Japan stopped him from disclosing any factual data, pointing to confidentiality. However, there seems to be a large contract for hybrid vehicles of an unnamed manufacturer.

There was another interesting disclosure that set Nidec apart from more European driven suppliers. The Asian company sees and forecasts growing demand for motors in the very compact EV segment. According to the company’s estimates, these are the secret sellers that will easily surpass Tesla. COO Seki pointed to small electric cars like the Chinese Mini EV “selling like fries” with numbers around 35,000 units a month and said Nidec was receiving many requests in that area. Indeed this could have repercussions – take the China Mini EV which GM is making at Wuling, which an Eastern European distributor decided to bring to Europe. Even VW has been pondering a low-cost ID.2 made in China for some time. Demand, we agree, will certainly accelerate – whether Nidec will supply more of the suppliers or move up to deal with more OEMs directly, time will tell. The company is getting ready.

Update 13 December 2021:

Nidec has started building a new traction motor plant in Serbia (almost) as planned. However, as described above, the company set construction to begin in September 2021, so it has moved to December. Regardless, Nidec says it will stick to the schedule despite the three-month delay.

This means the company continues to expect to complete the 59,760-square-meter Nidec Electric Motor Serbia production facility in the city of Novi Sad by mid-2022. The plan is to employ about 1,000 people in the first phase. Novi Sad is around 90 kilometres northwest of the Serbian capital Belgrade.

Update 06 July 2022:

After Nidec began construction of its electric traction motor plant in Serbia in December 2021, ground has now been broken for another of the company’s production facilities in the country. As reported above, the new Nidec Elesys plant will produce inverters and electronic control units for vehicles in an area of around 36,000 square metres and, like the electric drive system plant, will be built in Novi Sad, around 90 kilometres northwest of the Serbian capital Belgrade. Completion is planned for the beginning of 2023.

Update 12 October 2022:

Nidec has now completed the construction of its electric motor factory in Serbia. Series production of electric motors for the automotive industry is scheduled to start there in 2023 at the new plant in Novi Sad. In the first phase, Nidec Electric Motor Serbia plans to employ around 1,000 people.

The production facility for e-motors is one of two Nidec plants in Novi Sad, Serbia: Following the groundbreaking ceremony for the Nidec Elesys plant for inverters and electronic control units (see update of 06.07.2022), the construction of the second plant in Novi Sad is scheduled for completion in early 2023

>> Virtual press call and PI via email, nidec.com, nidec.com (update), nidec.com (update II), mynewsdesk.com (update III)

0 Comments