ARKEMA increases its Kynar® fluoropolymer capacities at its Chinese site

Arkema will invest to further increase its fluoropolymer production capacities in Changshu by 35% in 2022. Simultaneously, Arkema celebrates the first ten years of successful PVDF production at its Changshu site in China.

The increase in capacity is scheduled to come on stream before the end of 2022. This new investment is fueled by further strong demand in the lithium ion battery business as well as significant opportunities in the water filtration, construction coatings, and semiconductor industries.

Building and starting this plant in 2011 was a significant milestone for Arkema and continuing to grow this plant regularly is a source of great pride for the teams,” said Erwoan Pezron, Senior Vice President, High Performance Polymers. “We could not have taken such a step without the encouragement and support of our customers in the region. It is the same customer support that we count on for each successive investment including this latest step forward. We grow together. The first ten years has given us strong confidence in the future of this great facility and now we continue to invest in its exciting future.

Built in the context of the strong growth potential in Asia, and particularly in China, for the established coatings market and the rapidly emerging lithium ion battery and water-filtration markets, the Changshu plant was the Group’s third global integrated PVDF production plant. This plant, known as Arkema’s “Tiger Plant”, as it was constructed in 2010, the year of the Tiger, represented a major strategic step for Arkema in its commitment to supply global customers from each region. Arkema’s well-established Changshu platform was already an epicenter of fluorine chemistry and the location also placed its activities at the heart of its customer base. The plant was expanded several times over the decade and most recently in December 2020. Throughout its evolution, the plant has demonstrated an outstanding commitment to employee safety and product quality. It is a versatile state-of–the-art facility capable of producing almost every grade in the fluoropolymers expansive portfolio.

Kynar®PVDF solutions as electrodes binders and separator coatings in lithium-ion battery technology

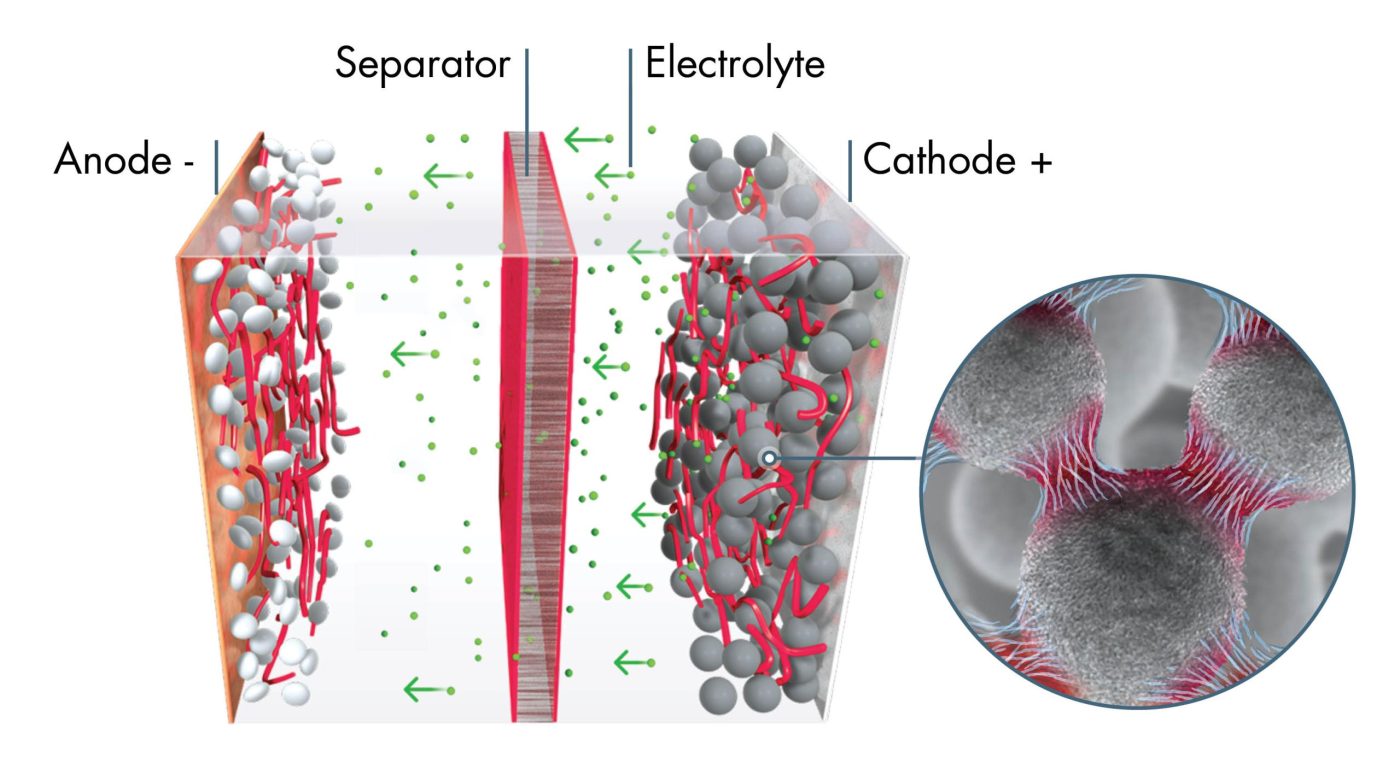

In lithium ion batteries, Kynar® PVDF is used in two applications inside the cell. It was first used as an electrode binder in typical consumer electronic devices using LCO active materials. The second massive wave came with the rise of electric Buses using LFP. Since last year, LFP has gained strong traction for usage in full EV as well outside China. Kynar® HSV 900 grade is the reference material for these binders bringing slurry stability, adhesion, flexibility and outstanding overall cell performance. In parallel, NMC cathode materials remain an important active material where Kynar® HSV1810 grade is gaining rapid recognition as a high-performance solution.

The second application is its use as an adhesive-type separator coating (dry or wet) between the separator and the electrode. Trusted by leaders, Kynarflex® LBG grade is the global gold standard material for this application. Its versatility for use in solvent and water-based processes make it unique. Kynarflex® LBG grade is a flagship product within Arkema’s much broader portfolio of Kynar® PVDF copolymers.

Arkema has been a world leader in PVDF production for several decades, and an innovating, pioneering supplier to the lithium-ion battery market since the very beginning. With such a proven record, Arkema is proud to engage with their partner customers on novel manufacturing processes and breakthrough new technologies such as solid-state batteries.

Battery Solutions by Arkema – a unique value proposition of high performance materials

Beyond Kynar® fluoropolymers, Arkema has the market leading technology portfolio of speciality materials for inside and outside the cell. Arkema’s solutions help to optimize performance and improve the battery energy density, duration, weight reduction and recharging time. Arkema’s market-leading portfolio includes applications from cell to module and battery pack assembly up to battery system integration into the vehicle.

More information on arkema.com.

This article is a paid advertorial. The client is responsible for the content. If you are interested in booking an advertorial, please contact us via advertise@electrive.com.

0 Comments