New Farasis battery cells offer 25% more range

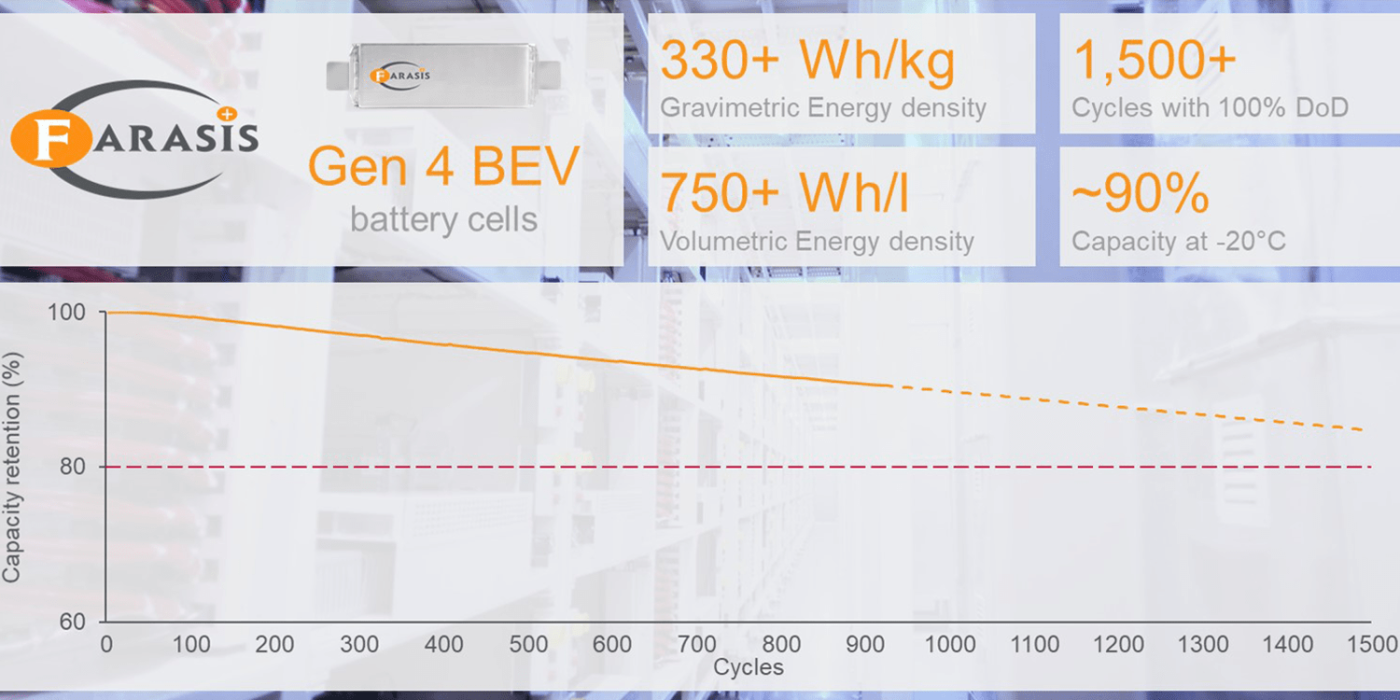

Daimler’s Chinese battery cell partner Farasis Energy has announced key figures for the fourth generation of its battery cell technology for electric cars. According to the company, the new cells will have an energy density of more than 330 Wh/kg and 750 Wh/l respectively.

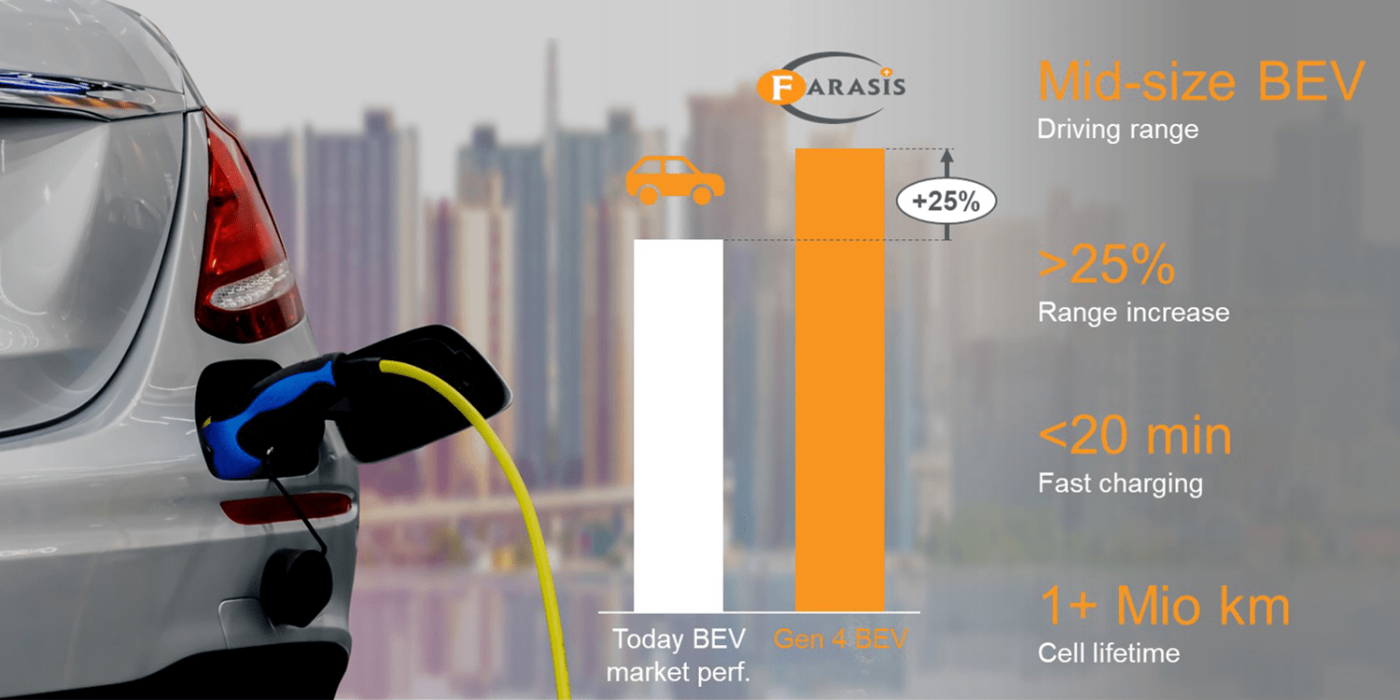

With these 330 Wh/kg, the energy density is more than 25 per cent higher compared to today’s norm values. Both this energy density and the performance of the new battery cells have also been confirmed by independent laboratories. With reference to current data, Farasis also expects the new cells to last for more than 1,500 cycles. And, he said, the new battery technology enables fast charging from 10 to 80% SoC in less than 20 minutes.

“We are very pleased to be able to present the validated results of our development work over the last few years today,” comments Farasis Chief Technology Officer Dr Keith Kepler on the cell presentation. According to him, the company is in a position to offer customers a more than 25% increase in energy density and, as a result, electric range, while at the same time reducing the fast charging time to less than 20 minutes.

The Chinese manufacturer emphasises that the new battery cell technology does not only work in the laboratory. Even at temperatures of -20°C, the fourth-generation cells are said to provide a capacity of more than 90%. Despite the significantly increased energy density, it has been possible to continuously increase the service life of the battery cells under the same charging rates. There is talk of an “achievable battery life of up to over 1 million kilometres”. In summary, Farasis claims to have improved all parameters of the cells.

This announcement comes only shortly after rumours of poor quality cell samples at the Chinese company: A month ago, Manager Magazin reported that the first cell samples supplied by Farasis to Daimler were “catastrophic“. Since Farasis is to supply about half of the cells required by Mercedes in Europe in the medium term, poor or unacceptable quality would have a massive impact on the Stuttgart company’s upcoming e-offensive. However, both Farasis and Daimler denied the media report. “We cannot confirm speculations about the quality of cell samples,” a Daimler spokesperson told electrive.net.

Farasis has fixed in its own technology roadmap that it wants to increase the energy density of battery cells for electromobility by up to 50% by the end of this decade compared to the current state of the art. Dr Yu Wang, CEO of Farasis Energy, sees the fourth generation of cells as an important stage on the way to this goal. “We believe that electric range as well as fast charging capability are the two key differentiators in the premium BEV segment. Due to its strong technology portfolio as well as its global manufacturing network, Farasis can offer the right solutions for this globally to provide its customers with technologically leading batteries worldwide.” As of early 2020, Farasis says it has a manufacturing capacity of 23 GWh per year. This figure is to be further expanded by setting up additional sites in China, Europe and the USA.

Farasis EU managing director Sebastian Wolf is quoted in the statement as saying that “our current Gen 4 technology is attracting a great deal of interest from our customers”. Farasis has already started first application projects and Wolf is convinced that “we will soon see many vehicles with this technology on the road”. According to Wolf, the new battery cells make it possible to increase the range “of an average mid-range BEV to well over 700 kilometres and thus to the level of modern passenger cars with internal combustion engines”.

Farasis announces that in the course of the rollout of the new cells it will set up so-called application engineering centres in Asia, Europe and the USA to support customers “in converting the 25% increase in energy density into electric range”. With its “data-driven approach”, the manufacturer wants to ensure maximum energy density under all operating conditions at module and pack level in these centres. “Together with our customers, we select the ideal integration strategy of the cells into the vehicle from our technology toolbox and also go significantly further than cell-to-pack,” Farasis specifies.

With reporting by Cora Werwitzke, France.

presseportal.de (in German)

0 Comments