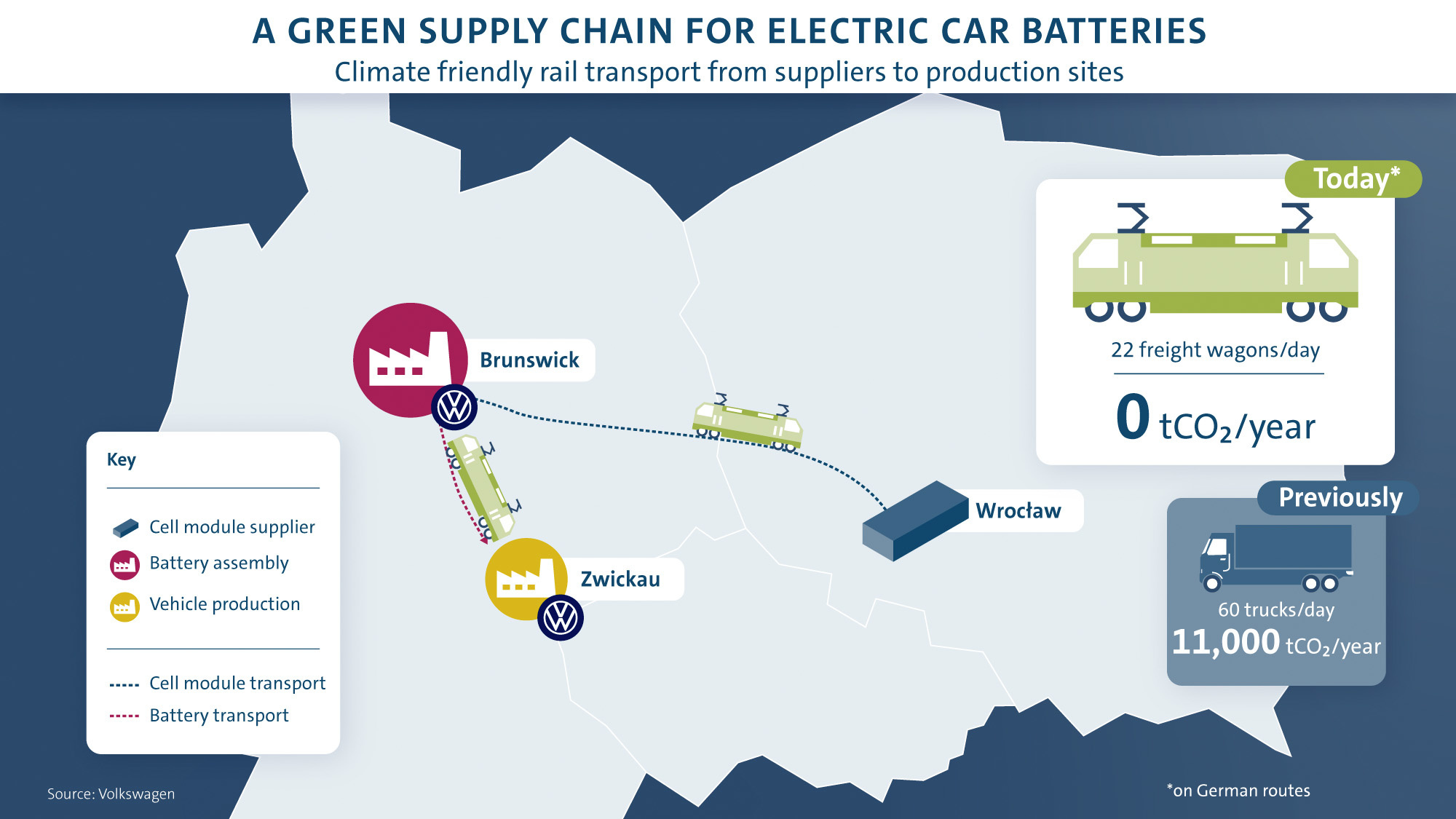

VW transports batteries to Zwickau by train

According to Volkswagen, “green battery logistics” have been put into operation for the MEB plant in Zwickau. Transporting the batteries by rail is expected to save around 11,000 tons of CO2 per year compared to truck transport.

The supply chain of the batteries for ID.3 and ID.4 goes from the Polish plant of the cell supplier LG Chem in Wroclaw, where the prefabricated modules are sent by train to Braunschweig. At the Volkswagen Group Components plant they are assembled into ready-to-install battery systems. These are then transported by rail to Zwickau.

The last part of this logistics chain, which has now been put into operation, is a plant that unloads battery systems fully automatically from the arriving trains. “The environmentally friendly transport of the batteries is another important piece of the puzzle on the way to an emission-free factory as part of the cross-brand sustainability strategy ‘goTOzero’,” said Reinhard de Vries, Managing Director Technology & Logistics Volkswagen Sachsen, at the commissioning of the plant in Zwickau.

Strictly speaking, there are two such plants in the supply chain. In Braunschweig, the modules are moved by a similar loading and unloading station: Since the assembly hall has no rail connection, the modules and battery systems are transported between the Harvesse de-forestation station and the hall by electric truck.

VW has developed its own special containers for battery logistics. According to the company, these should be able to hold both the modules and the fully assembled systems, making the containers suitable for both stages. The containers were designed to ensure that the wagons are used to their maximum capacity in terms of weight and volume.

Currently, five trains per week run between Braunschweig and Zwickau and Volkswagen says the frequency of the trips is expected to increase even further. The journeys are carried out by DB Cargo. In Germany, these are to be carried out exclusively with green electricity.

0 Comments