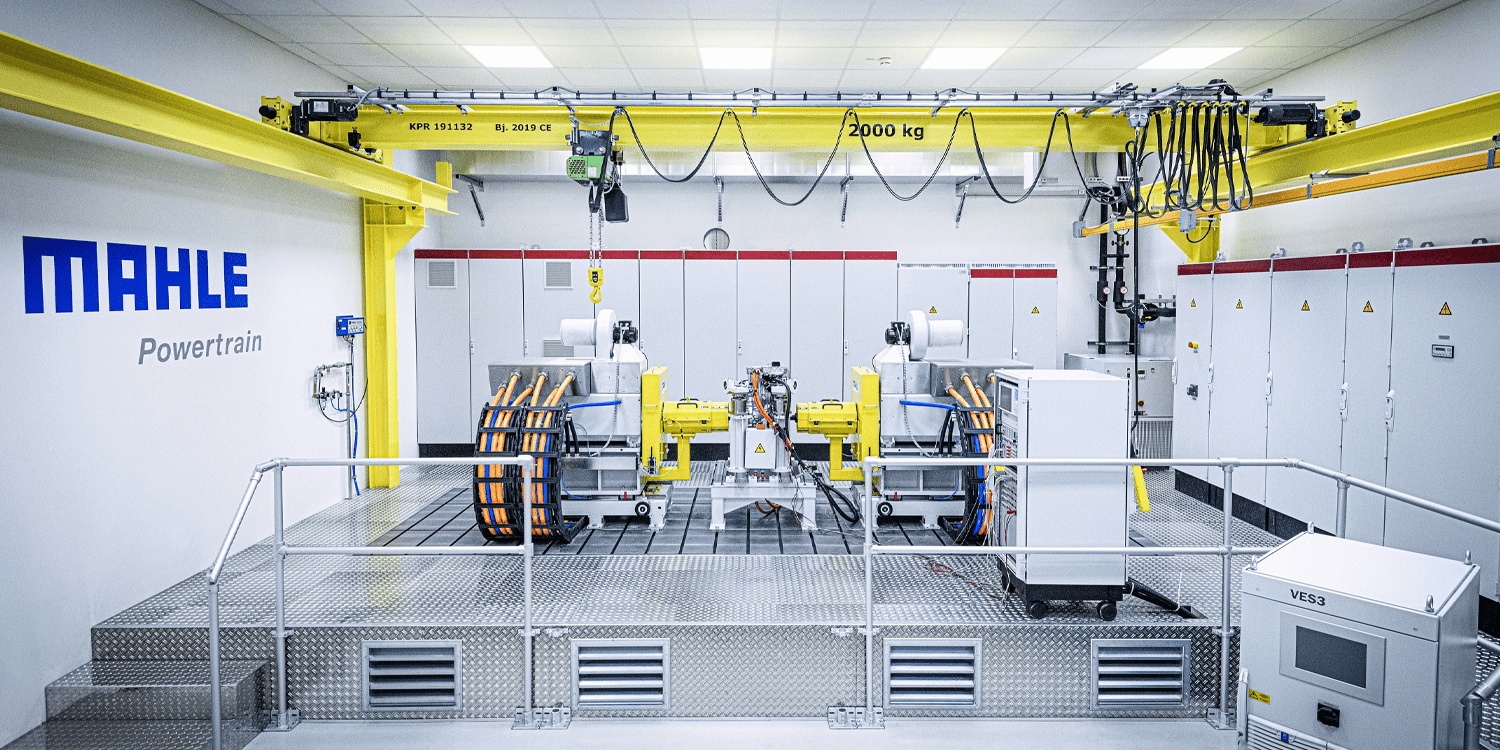

Mahle opens electric axle drive testing facility

The automotive supplier Mahle has opened a new test bench for electric drives in Fellbach near Stuttgart, Germany. In the future, individual drive units and complete electric axle drives for electric cars and plug-in hybrids will be tested there. The first test for a customer has already been completed.

Mahle says that the three-million-euro test stand was inaugurated with a power unit test from the first customer. At the facility in Fellbach, not far from Mahle’s headquarters in Stuttgart, “functional development work, simulate highly dynamic, transient modes of operation, perform efficiency measurements and torque vectoring, and simulate wheel slip scenarios” are to be carried out for international customers. The usual test bench work, i.e. the creation of characteristic diagrams or tests of thermal influences should be possible for me in high- and low voltage systems.

The spectrum of services should be broad. According to the supplier, individual functions could be tested in around 200 hours of operation. An endurance test could also be carried out for a whole year.

The electric axle system consists of two load machines arranged opposite each other. For each test stand, the permanent magnet-excited synchronous electric motors are to provide a nominal load capacity of 350 kW and a peak torque of 8,400 Nm (7,000 Nm continuous torque). The voltage spectrum of the tested drives (including separate battery simulation) covers the range from 48 to 1,000 volts. In order to simulate the temperatures that occur during vehicle operation, the facility has an air-conditioning system that, according to Mahle, should be able to precisely simulate the range from -30 to 130 degrees Celsius.

“With the commissioning of the test bench, Mahle continues the targeted expansion of its global range of services for e-mobility,” says Martin Berger, Head of Research and Advanced Development at the company. “Both our customers and our developers can now benefit from an ultramodern facility, which is one of only very few in Germany”.

With the ramp-up of electromobility, numerous companies in the German motor industry are currently investing in appropriately designed inspection and test centres along the entire life cycle of the vehicle, from pre-development to testing of existing vehicles. In September, TÜV SÜD opened a test centre in Heimsheim, where hybrid and electric vehicles can be tested for type approval. In October, TÜV Rheinland had announced a test laboratory for electric car drive batteries. The SGS e-mobility laboratory, which opened in July, is not only designed for traction batteries but also for charging technology such as plug connections for high- and low-voltage lines. FEV, the Aachen-based vehicle development service provider, commissioned a development and test centre for high-voltage batteries called eDLP at its Sandersdorf-Brehna site in Saxony-Anhalt in the third quarter of this year.

0 Comments