Europe gets help from China & Tesla on battery cells

The European Battery Alliance has reached more than 500 members from the industry three years after its foundation. At the European Conference on Batteries, politicians and entrepreneurs discussed the future of battery production in Europe with a prominent guest from California.

EU Commissioner Maros Sefcovic mentioned the number of 500 participants in the Battery Alliance in a speech at the start of the European Conference on Battery Cell Production, which is being organised by the German Federal Ministry of Economic Affairs and Technology as part of the German EU Council Presidency. “The Alliance was created to build a globally competitive, innovative and sustainable European battery value chain, amounting to an expected market value of 250 billion euros by 2025,” said Sefcovic.

At the digital conference, the host, Federal Minister for Economic Affairs Peter Altmaier, also repeated the goal of a complete value chain for battery cells in Europe, “from the processing of raw materials to battery cell production to recycling”. The Federal Ministry of Economic Affairs is therefore funding the German projects within the two battery IPCEIs with almost three billion euros, Altmaier said. Their plan is that in future, innovative and environmentally friendly battery cells are to come from Europe, creating tens of thousands of jobs along the value chain.

It is clear that international companies will also make a decisive contribution to this European value chain. CATL is building its cell factory near Erfurt, while SVOLT, also a Chinese manufacturer, announced last week that it will set up its European production facility, including a future research centre in Saarland, investing up to two billion euros.

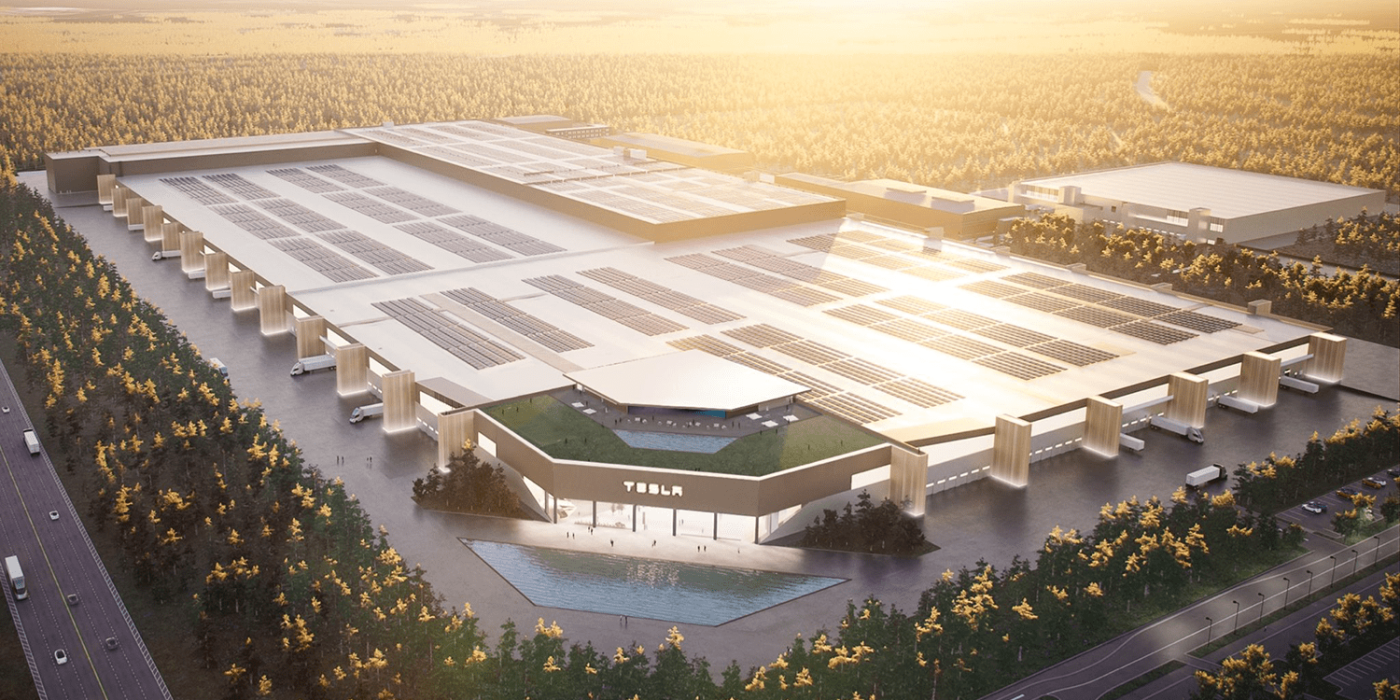

The most prominent representative from the industry was not from Germany or China but from California. In a short discussion, Tesla CEO Elon Musk gave some insights into the planned battery cell production in the Brandenburg Gigafactory, concrete effects on vehicle projects, but also general goals of the company in battery research.

“Building the prototype of an advanced technology is easy,” says Musk. “But scaling up mass production is extremely difficult.” In his view, there will continue to be improvements in energy density and thus range, rapid charging capability or battery cell life. “The biggest factor is cost. This is the biggest lever for the spread of electric cars,” says the Tesla CEO.

Tesla wants to achieve 50 cents per kilowatt-hour

His long-term goal is 50 cents per kilowatt-hour at the cell level for a “long-range battery cell”, i.e. not a prototype. The consulting firm Strategy& had only predicted costs of 68 euros/kWh in 2030 in September, costs in the cent range seem difficult to imagine.

Musk’s plan, which had already been hinted at the ‘Battery Day’ in September. For Musk’s plan, the design of the battery cell must be adapted and above all the factory where the optimised cell is built. “The cell must be built in the right way,” says Musk. “But the bigger challenge is to safely and reliably ramp up production. We have made great progress here with acquisitions, including Grohmann”.

An important advance in the design and production of the cell comes from another acquisition whereby Tesla is relying on dry electrode technology with the know-how of Maxwell Technologies. “The dry electrode production process is a game-changer. It not only makes production cleaner because we no longer have to use solvents,” explained Musk. “There are also advantages in the manufacturing process because we can apply the material more precisely, we don’t have to dry the paste and we don’t have to collect and filter the gases generated during drying”.

Production process more important than cell design

While Maxwell is still optimising the process and materials, Tesla is already thinking about production. “With the shortened cycle times in production and the extreme precision required at the same time, we have to develop new machines,” says Musk, again referring to Grohmann. “It sounds simple, but it wasn’t. There are no such machines, we are developing them first – in Germany and with other countries in Europe.”

This dry-electrode technology will then apparently also be used in Grünheide with further challenges. In Fremont, Tesla operates a pilot plant at its Tera production facility, a “proof of concept”, as Musk calls it. “When you see our pilot plant in California, you get an idea of how complex a production facility will be that is 100 times larger,” says the Tesla boss.

He apparently has big plans for Brandenburg: a capacity of 100 GWh per year is possible. “I can even imagine expanding to 200 to 250 GWh,” says Musk. “I’m pretty sure that that would make it the largest battery factory in the world.

Not only the Model Y built in Brandenburg should then benefit from the new, low-cost cells, but also the Tesla Semi electric truck. Here, Musk envisaged ranges of 800 and later 1,000 kilometres, with batteries becoming lighter at the same time. The 4680 cells are also to be integrated into the structure of the battery itself and thus become a supporting part. “We already have several prototypes of the Semi in operation,” says Musk. “I think that this will be very interesting for logisticians.”

With reporting by Sebastian Schaal, Germany.

Source: conference live stream (statements by Musk), reuters.com, europa.eu, bmwi.de (in German), finanzen.at (in German)

0 Comments