SK Innovation’s new quick-charge cells for 2021

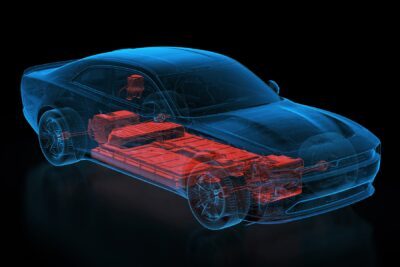

SK Innovation has announced new battery cells that will enable electric cars to cover a distance of 500 miles or 800 kilometres with two 10-minute quick charge stops. In addition, a cathode with a higher nickel content is expected to go into series production shortly.

The new cells, for which SKI gives little information about the chemistry, are to be fully developed by the first half of 2021 at the latest. According to the company, they will “be able to play an important role in the spread of electric vehicles”. The announcement, which was made at the InterBattery battery conference sponsored by the South Korean government, merely stated that the new cells are designed for more than 1,000 charge cycles and are to have higher energy densities.

SK Innovation is known to be the cell supplier for the VW ID.4 from US production. Production of the VW ID.4 is scheduled to start at the Chattanooga plant in 2022, which means that it is possible, at least in terms of timing, that this type of cell will be used in the Volkswagen electric SUV.

SK Innovation had decided to concentrate its development efforts on “long-life batteries that enable long-distance journeys”. A family SUV like the ID.4 would fit into this scheme. This is probably also a question of incorporating higher storage capacities in smaller battery packs. Small cars, for example, should be able to offer longer ranges – despite their small installation space – and should also be suitable for long-distance travel thanks to their quick-charging capability with only short charging pauses.

In order to fulfil the “long-cherished wish of the EV industry” for high-speed charging, the company has developed cells that only need to be charged twice for ten minutes on an 800-kilometre route. SKI has not provided further details about this theoretical trip in the communication. Assuming that the battery was fully charged at the start of the trip and that the two stops for charging do not reach 100 per cent SoC, this would still mean that during a ten-minute stop for charging, electricity would flow into the battery for an estimated 150 to 200 kilometres.

SKI became somewhat more concrete with a long-distance battery, which is said to have already achieved a range of 1,000 kilometres under optimal driving conditions during a test drive. The core is to be a NCM9½½ cathode, i.e. with a higher nickel content than the NCM622 and NCM811. Conversely, the proportion of cobalt and manganese will drop to five per cent each. The new cathode is apparently soon to go into series production.

An update on the legal dispute with LG Chem whereby both South Korean companies accuse each other of patent infringement was not explicitly mentioned in the announcement. Nevertheless, it appears the company could not refrain from taking a dig at its South Korean competitors. The press release states that SKI has been supplying batteries for electric cars and plug-in hybrids for ten years, “without a single battery fire”.

Both the Hyundai Kona Electric and the Chevrolet Bolt EV have recently experienced problems with vehicle fires. Both models rely on battery cells from LG Chem, and LG is aware of its responsibility, at least in the case of the Kona. However, it must also be said that SK Innovation has not yet produced EV battery cells in the same size as Panasonic, LG Chem or CATL. Then again, Kia’s e-Niro, which shares most of the drive technology with the Hyundai Kona, gets its batteries from SK Innovation rather than its competitor LG Chem and has had no such battery problems so far.

1 Comment