FST & Quantron develop heavy truck FC system

In Germany, Freudenberg Sealing Technologies has launched the development of a fuel cell system for trucks in the 40-ton weight class. The company is cooperating with commercial vehicle conversion company Quantron.

Quantron announced the Energon fuel cell truck in June. Now, the first test vehicle should test performance, durability and range under continuous commercial driving conditions on Bavarian roads from mid-2021.

The project funded by the Bavarian state government is one of the first projects explicitly dedicated to the development of a fuel cell for use in heavy commercial vehicles. Fuel cell systems already available on the market today were originally developed for passenger cars. “Truck systems, in contrast, require a service life of at least 35,000 hours. This is because commercial vehicles earn money exclusively through reliable, continuous operation,” explains the manufacturer, who in 2019 has already launched development projects for FC buses and cruise ships with partners such as FlixBus and Meyer Werft.

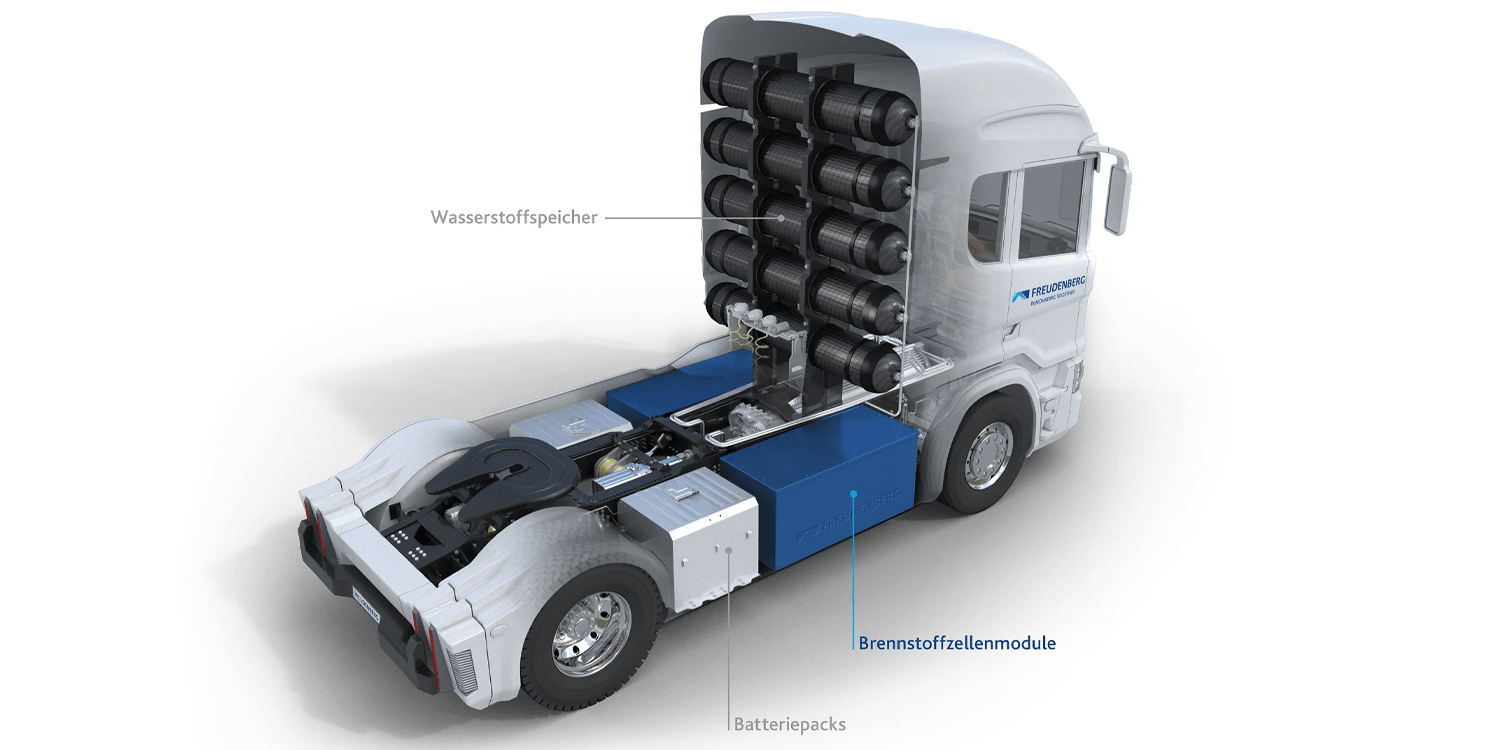

Key data on the Energon heavy-duty truck has already been published, allowing conclusions to be drawn about the FC system on which Freudenberg and Quantron are currently working: The fuel cell system will have an output of 130 kW. Along with an LFP battery with a capacity of 110 kWh for which CATL supplies Quantron with cells, the fuel cell will feed a 340 kW motor. The powertrain also has a two-speed transmission. The vehicle being converted is the Iveco Strator long hood truck.

“Fuel cell trucks are the only economical, emission-free alternative that permits large payloads as well as significant ranges and fast refuelling cycles,” says Dr Manfred Stefener, Vice President Fuel Cell Systems at Freudenberg Sealing Technologies. “That’s why we are looking forward to working with Quantron AG to create fuel cell applications that are explicitly designed for the maximum load and operating points of trucks.” The aim is to make a fuel cell specifically for long service life and heavy-duty profiles that can outshine diesel in terms of the total cost of ownership. This should bring a sustainable, emission-free alternative for heavy-duty traffic to market.

In addition to the powertrain, the project partners are striving for further innovations, such as the use of particularly robust material combinations, or the development of interfaces for a space-optimised application in commercial vehicles.

Onboard with the project is Quantron AG, a company that recently announced its intention to develop from a commercial vehicle retrofitter to a full-range provider of complete electrified solutions. The Augsburg-based company is also aiming for a listing on the stock exchange.

Quantron itself was founded in 2019. The idea for the company was born under the company Haller based in Gesthofen, Germany. Quantron began as an Iveco contract partner and commercial vehicle specialist providing versions of the Iveco Daily converted to hybrid or electric drives. The business soon grew beyond conversions (also of trucks and buses), and as early as November 2019, an exclusive agreement was concluded with the Turkish bus manufacturer Karsan for the distribution of the Jest Electric and Atak Electric buses in Germany. In April this year, less than 12 months after its foundation, Quantron became the sales and after-sales partner for commercial vehicles and industrial applications for CATL in Europe.

By contrast, the Freudenberg Group has been in the eMobility business for a long time. As early as the mid-1990s, it began developing technical components for fuel cells and batteries. In the last two years, the company has further strengthened its position in this field with the acquisition of the FC manufacturer Elcore and, shortly afterwards, a stake in the US battery manufacturer XALT Energy. Freudenberg Sealing Technologies considers the resulting depth of added value to be a major plus: “The in-house production of gas diffusion layers, permeable sealing materials and catalysts forms the basis for fully integrated membrane-electrode assembly (MEA) and offers the starting point for truck fuel cells of the future.” Claus Möhlenkamp, the company’s CEO, confirms that assembling only bought-in components is not a solution for the heavy-duty fuel cells of the future in large quantities.

0 Comments