Porsche & Customcells consider battery factory in Germany

Porsche and the Fraunhofer spin-off Customcells apparently want to build a battery cell factory in Tübingen. The endeavour is still missing EU approval that would enable state funding.

The German newspaper Tagesspiegel Background cited industry circles, saying the cell manufacturer Customcells is to develop battery cells with Porsche for the next generation of the VW subsidiary’s electric sports cars. The two partners have already founded the joint venture called Cellforce Group for this purpose, and production will be located in Tübingen, south of Stuttgart.

The project still has to gain approval from the EU whereby the project would be classified as an IPCEI project (Important Project of Common European Interest), which would enable state funding. So far, the IPCEI project has funded the planned battery cell production of the PSA subsidiary Opel in Kaiserslautern and the battery cell production of BMW in Parsdorf near Munich, which was announced a few weeks ago. In total, the German government intends to invest around three billion euros in various battery cell projects.

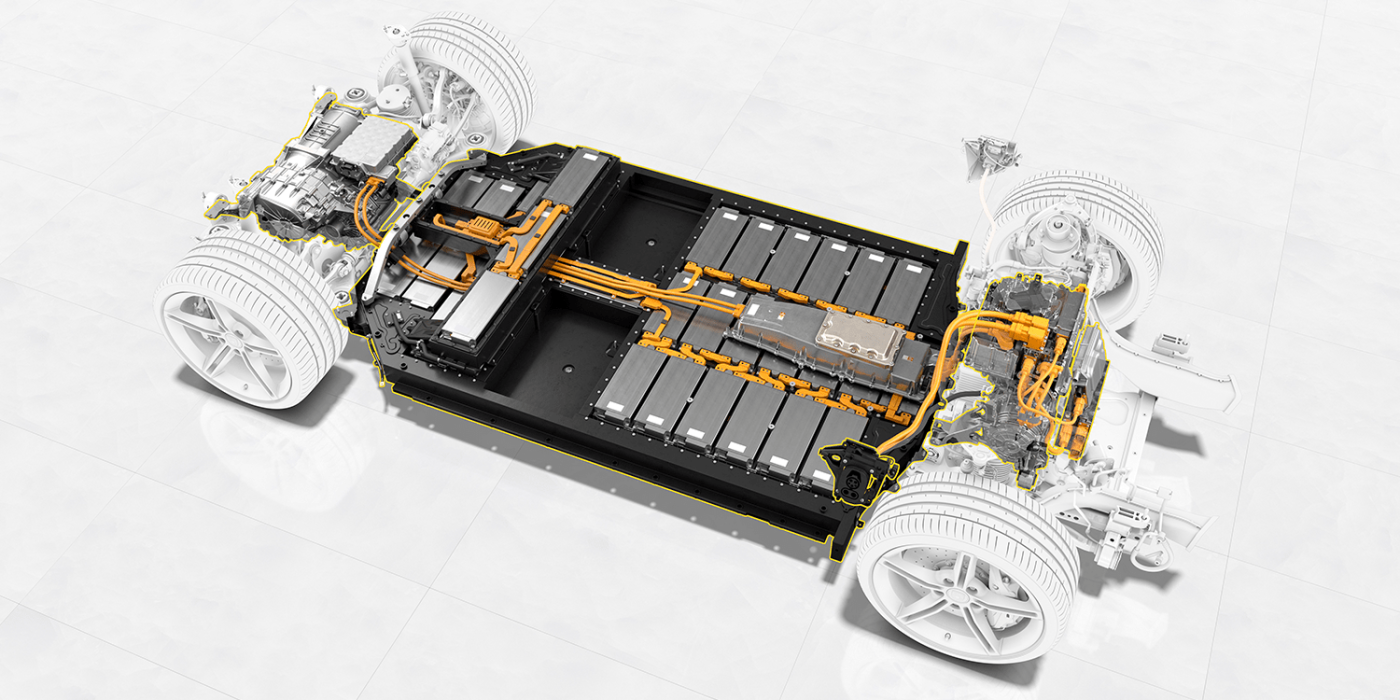

The production capacity of the planned factory in Tübingen was not extrapolated upon, but Tagesspiegel newspaper said that “rather small quantities of high-performance storage units with high energy density and low internal resistance” are planned to enable short charging times and long ranges in Porsche’s premium electric cars. A production capacity in the gigawatt range is conceivable in the medium term.

The Tübingen site was chosen not only because of its proximity to Porsche’s main Zuffenhausen plant where the Taycan is being built but also because of its existing facilities. In the KomVar research project, in which Customcells, P3 Automotive and the Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) are involved, a research production facility for lithium-ion cells has already been established in Tübingen. In October 2019, Porsche said that the facilities will be able to produce different cell designs and cell technologies in large series quality despite small and medium quantities.

Daimler was an associated partner of KomVar at that time. It is still unclear why Porsche and not Daimler is now setting up such series production using the findings from the research project. One possible explanation is that Daimler may have decided to work with other partners. It was only at the beginning of July that the company announced its entry into the Chinese battery cell manufacturer Farasis to supply the German Mercedes plants from the planned factory in Bitterfeld-Wolfen, among other places. In addition, Daimler entered into a closer partnership with CATL only last week.

Porsche has been purchasing the cells for the Taycan from LG Chem, while the battery itself is pre-assembled by supplier Dräxlmaier and delivered to Zuffenhausen. Porsche is very satisfied with the Taycan’s sales figures so far, but higher quantities are expected for the next generation of the Macan, which will also be offered as an electric SUV.

Customcells was spun off from the Fraunhofer Institute for Silicon Technology in 2012. The Itzehoe-based company describes itself as one of the leading suppliers of “special lithium-ion cells”, or more precisely of “application-specific battery cells from prototypes to small and medium-sized series”.

tagesspiegel.de (in German)

0 Comments