Northvolt becomes 3rd battery cell supplier to BMW

The BMW Group has signed a long-term supply contract for battery cells with the Swedish company Northvolt. The deal is worth two billion euros. Northvolt will start manufacturing the cells in 2024 in its Gigafactory in Skellefteå, currently under construction.

The Swedish company is already the third supplier to the Munich company after CATL and Samsung SDI. For BMW, the multi-supplier strategy is to establish global competition within the Group’s network, according to press information. Andreas Wendt, member of the Board of Management of BMW AG responsible for Purchasing and Supplier Network, explains this way, they ensure “we always have access to the best possible cell technology”.

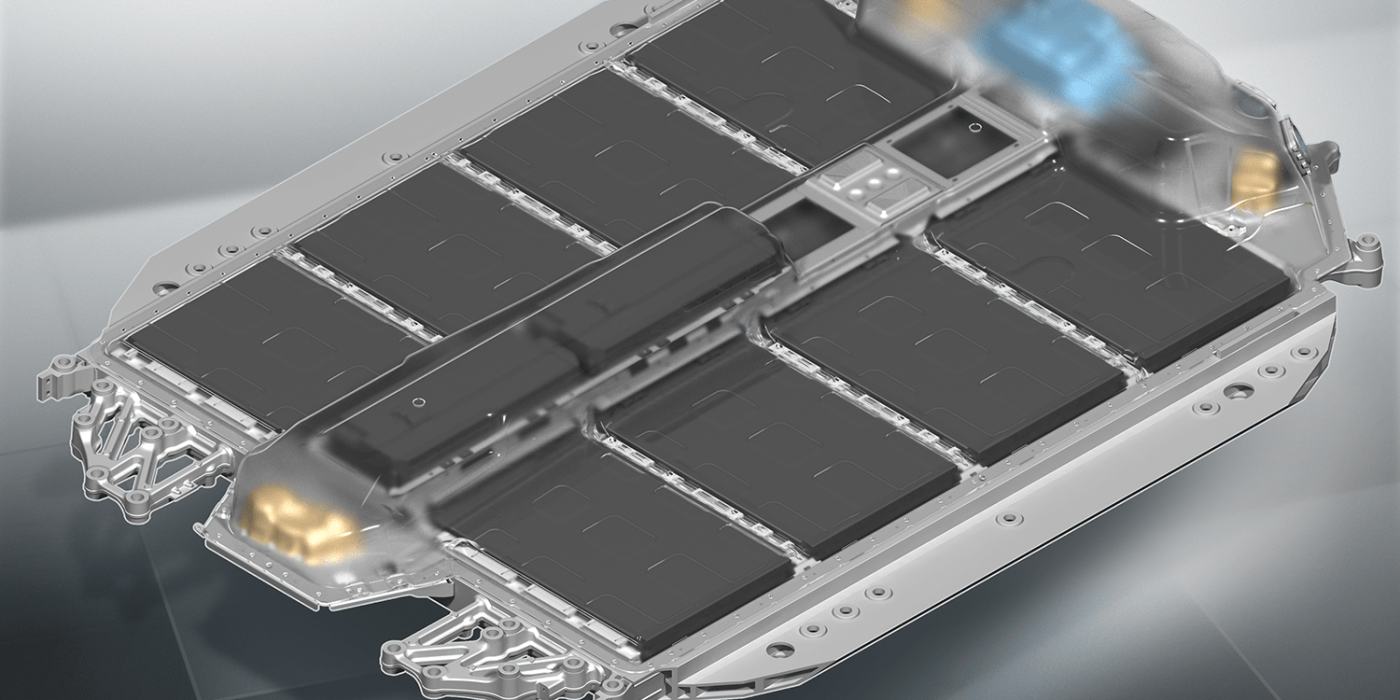

BMW said nothing about the term of the contract with Northvolt, which also supplies Volkswagen. The Nortvolt-Volkswagen deal sees them building a cell factory in Salzgitter at the moment. BMW, however, only assembles the batteries for its electric vehicles at its facilities in Germany, China, the US and Thailand, but buys the cells from said partners.

On signing the latest contract with Nortvolt, Wendt added that it is “another step towards meeting our growing need for battery cells in the long term”. In the communication the Bavarians also stress, they had recognised Northvolt’s “potential and expertise early” as they entered a cooperation to develop battery cells back in mid-2018 through forming a joint technology consortium. Together with Umicore, the partners are looking into more sustainable cells. For these, recyclable cell design is a consistent focus throughout the development of battery cells, claims BMW.

These green ideas also inform the agreement with CATL, Samsung SDI and Northvolt, all include the premise only to use power from renewables to produce fifth-generation battery cells for the BMW Group. “As volumes increase, the use of green power will save around ten million tonnes of CO2 over the next decade. For comparison, that is roughly the amount of CO2 a city of over a million inhabitants, like Munich, emits per year,” according to BMW CEO Oliver Zipse.

Sustainability has moved up on the public BMW agenda in recent months. BMW announced in October 2019 that it was changing its strategy for purchasing raw materials for battery materials. The car manufacturer will buy cobalt and lithium, for example, from the mine operators themselves and then make it available to cell manufacturers to build battery cells for BMW. This is supposed to eliminate suppliers and go-betweens from the supply chain, and the German company hopes that it will provide greater control and greater transparency. For this reason, BMW also initiated the organisation PartChain that uses blockchain technology to increase transparency in worldwide supply chains for raw materials and components. Only last week, BMW also signed a Cobalt supply agreement with Morocco reportedly.

The BMW Group operates its Battery Cell Competence Centre in Munich. The Group is working on prototypes there to analyse and better understand cell value creation processes. Recent rumours according to which BMW is planning a pilot plant for the production of battery cells for electric cars in the Bavarian district of Parsdorf, near Munich, remain unconfirmed. However, the plant would be the next step, following the developments of the centre to include first application scenarios.

What capacity for how many vehicles BMW will receive from Northvolt for the two billion euros is not clear from the notification. Northvolt Ett in Sweden will start in 2021 with a capacity of 32 GWh and will be expanded to 40 GWh by 2024.

Northvolt’s CEO Peter Carlsson said in November 2019 that his company is aiming for production capacities of around 150 GWh and a market share of 25 per cent in Europe by 2030. “There is no doubt that our ambitions go far beyond 64 GWh,” Carlsson told the Financial Times. He has now found an important major customer.

0 Comments