BMW orders cobalt from Morocco for €100M

The BMW Group has signed a supply contract with the Moroccan mining company Managem Group for cobalt for use in battery cells worth around 100 million euros. According to the German carmaker, this five-year contract covers around one-fifth of the cobalt requirements.

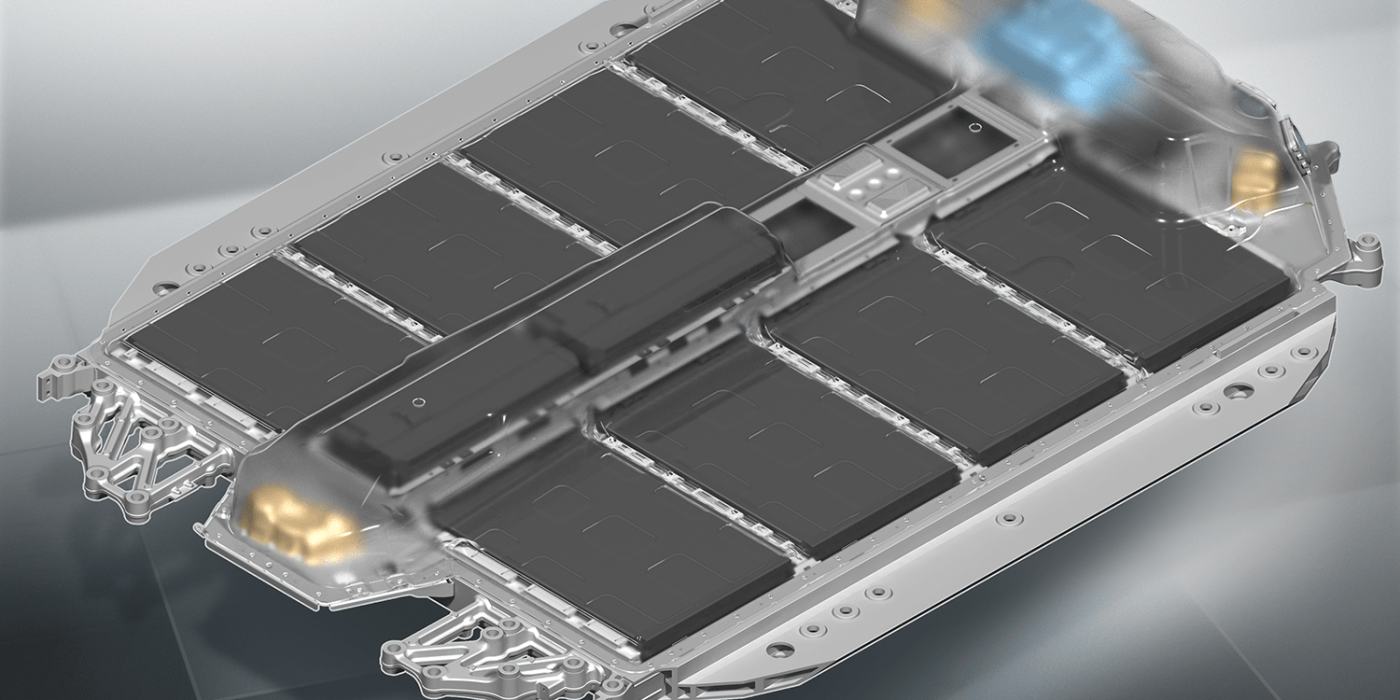

The two companies already signed a memorandum of understanding regarding the direct purchase of cobalt from Morocco in Marrakesh in January 2019. BMW will use the cobalt to supply the battery cells for electric cars using the company’s fifth-generation electric drives. The first of these vehicles to be launched on the market this year is the iX3. BMW will obtain the remaining four-fifths of the cobalt it needs from Australia as well as lithium.

BMW announced in October 2019 that it was changing its strategy for purchasing raw materials for battery materials. The car manufacturer will buy cobalt and lithium, for example, from the mine operators themselves and then make it available to cell manufacturers (currently CATL and Samsung SDI) to build battery cells for BMW. This is supposed to eliminate suppliers and go-betweens from the supply chain, and the German company hopes that it will provide greater control and greater transparency. For this reason, BMW also initiated the organisation PartChain that uses blockchain technology to increase transparency in worldwide supply chains for raw materials and components. Other carmakers such as Volvo are also making the origin of cobalt traceable using blockchain technology.

“By signing today’s supply contract with Managem, we are further securing our raw material requirements for battery cells,” says Andreas Wendt, BMW AG Board Member for Purchasing and Supplier Network. “By 2023, we want to have 25 electrified models in our range, more than half of which will be fully electric. The demand for raw materials is rising accordingly. For cobalt alone, we expect our current demand to roughly triple by 2025”.

Much of the cobalt traded worldwide is mined in the Democratic Republic of Congo. Cobalt from the Congo has come under increasing international scrutiny since cobalt is mined there by hand (partly with child labour and without adherence to safety standards) in addition to large corporations (such as Glencore) with their correspondingly industrialised mines. BMW already announced in 2019 that it no longer wanted to obtain cobalt from the Congo. Despite this, at the opening of the Battery Cell Competence Centre in November 2019, BMW’s materials purchaser Peter Zisch announced this option would not necessarily be excluded in the future. “We do not want to exclude the Congo, it is our declared aim to source in the Congo again,” said Zisch. “We believe that we can do this again from targeted mines from 2025 onwards.” In cooperation, BMW, BASF and Samsung SDI, are already supporting corresponding projects in Congo to establish clean and transparent cobalt extraction there.

In the current press release, Wendt also emphasises that cobalt and other raw materials must be “extracted and processed under ethically responsible conditions. The company has agreed with Managem on “the highest standards of sustainability”. In a list published by BMW of the suppliers and countries of origin of cobalt, Finland, Madagascar and Russia are mentioned in addition to Australia and the Congo, although the list is dated June 2019.

0 Comments