Autostack Industrie makes progress on fuel cell stacks

An update was published on the progress of the German ‘AutoStack Industrie’ project launched in 2017. The project will run until the end of 2021, involving five OEMs and various suppliers working together to bring key technologies for the production of stacks for fuel cell vehicles to industrial maturity.

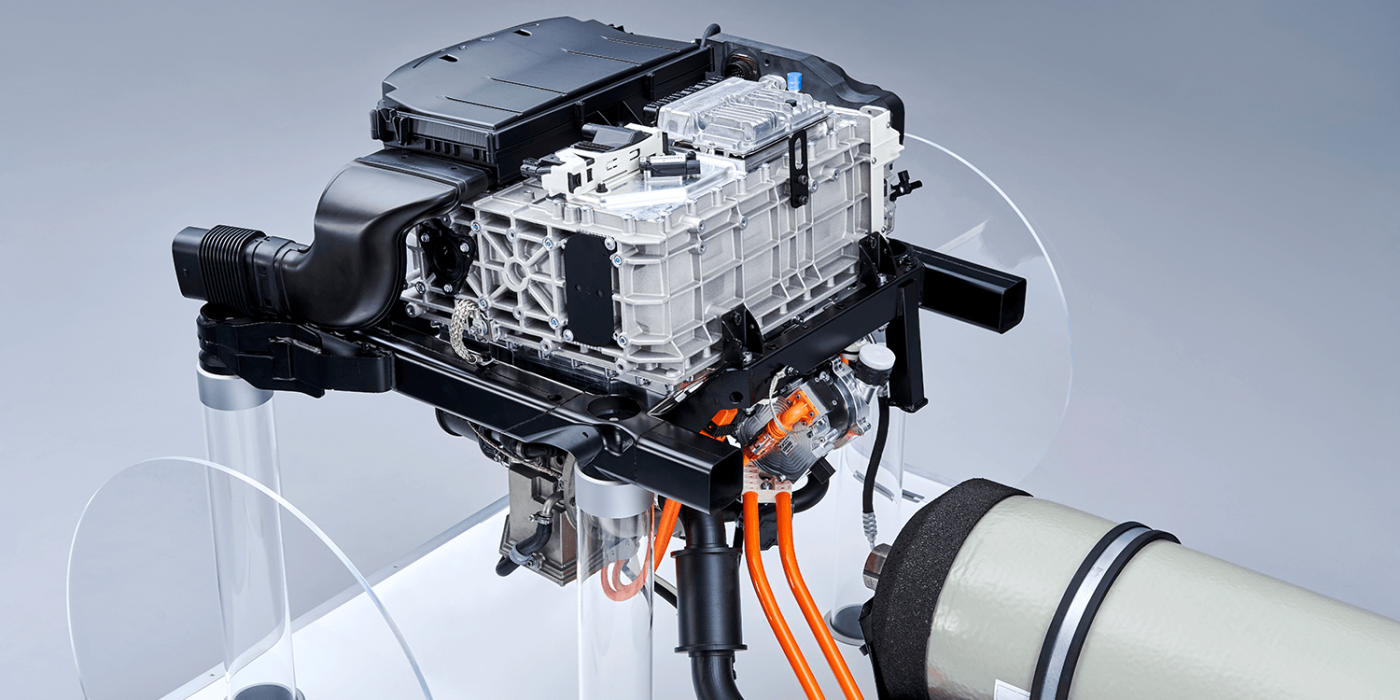

The Project has now announced that the first development phase (Evolution 1) of the stack development was completed at the end of March 2020 and the progress achieved has been evaluated. The OEMs have agreed on a specification and a basic system description with the corresponding interfaces. Around 60 stacks are to be built in two development phases by 2021. These will then be tested by the participating OEMs, ZSW and other project partners. Different stack sizes will be used depending on the test objectives. The specified reference power of the stack is 85 kW.

The stack developed in the project should also be suitable for mass production; the update on the project’s progress mentions 10,000 to 30,000 stacks per year. “With sufficient time it will thus be possible to prepare for the production of a large number of vehicles through the development and testing of industrialization-ready high-speed processes for stack manufacture and be able to meet future market demands in appropriate phases,” says project coordinator André Martin. The aim is to have a stack product and a manufacturing process that can be transferred to an industrial scale within 18 to 24 months after the project’s completion. That would then be 2023 or 2024 – roughly the time frame in which BMW, for example, wants to bring its small series of fuel cells to market.

While Martin is satisfied with the developments to date and, above all, the work processes between the companies involved, there are still a few hurdles to overcome before the fuel cells are ready for series production. Durability is one such issue: The project has defined the level of degradation at ten per cent over 6,000 operating hours was defined as “reliable” – a value that has apparently not yet been reached. The degradation takes place mainly in the membrane electrode assembly (MEA), other components such as the bipolar plate, the gas diffusion layer (GDL) and the catalysts are less affected. Stress factors such as temperature, pressure and humidity in the dynamic load change affect the MEA. According to Martin, development in this regard is time-consuming.

For the targeted production in larger quantities, the time required for stack commissioning must also be significantly reduced. Currently, the process in which the electrochemical components of the stack are activated takes several hours, while this may only be “a few minutes” in series production. In order to develop a suitable procedure for this an enormous amount of testing is required.

The project, which was launched in 2017, is being funded by the Federal Ministry of Transport and Digital Infrastructure (BMVI) with 30 million euros as part of the National Innovation Programme Hydrogen and Fuel Cell Technology (NIP). Besides ZSW, the four OEMs BMW, Daimler, Ford and Volkswagen as well as various suppliers are involved. Audi, the brand responsible for FC development in the Volkswagen group, has recently joined the group. How Daimler’s participation will continue is not clear from the project update – as reported, the Stuttgart-based company will contribute its fuel cell expertise to a joint venture with Volvo for the development of commercial vehicles. Here, Daimler appears to have recognised the benefit of hydrogen fuel cell technology for larger, heavy-duty and long-distance vehicles, while the GLC F-Cell car has not been given a successor.

4 Comments