BReCycle project to analyse fuel cell recycling

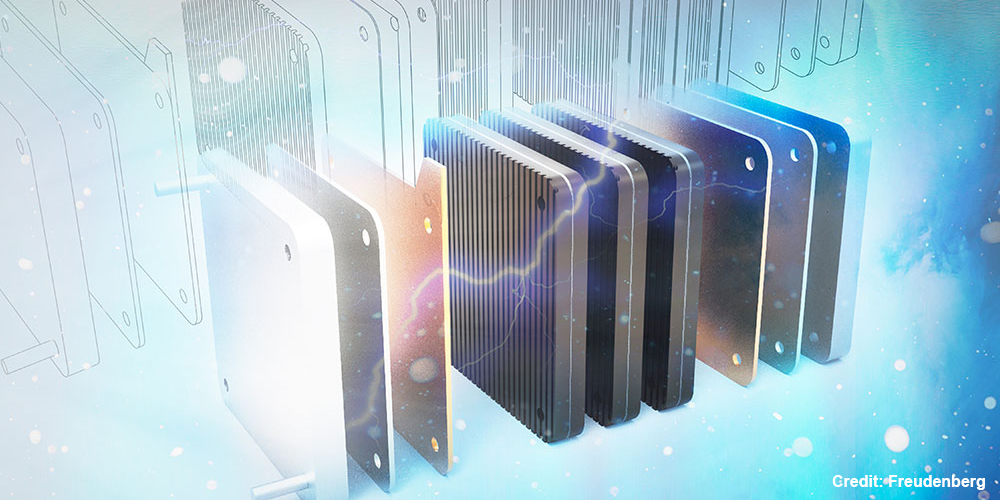

The BReCycle project now launched, sees five research and industrial partners working on a closed-loop economic concept for PEM fuel cells. The aim is to develop a sustainable process for the treatment of fuel cells.

The Fraunhofer Institute for Material Cycles and Resource Strategy (IWKS) asserts that it must be possible to separate the high-quality materials and the polymer membrane for recycling purposes, as they write in a communication. The project consortium led by the Fraunhofer IWKS includes Proton Motor Fuel Cell GmbH, MAIREC Edelmetallgesellschaft mbH, Electrocycling GmbH and KLEIN Anlagenbau AG. The German Federal Ministry of Economics and Energy supports the project.

Currently, there is no tailor-made recycling process on an industrial scale for polymer electrolyte membrane fuel cells (PEMFC). This type of fuel cell is already being used for automotive applications. With the increasing spread of the technology, researchers expect a “larger quantity” of fuel cells to reach the end of their life cycle by 2030 at the latest. Because of the high proportion of valuable technology metals and ecological considerations, they say, efficient recycling of materials contained in PEM fuel cells is necessary. These include platinum and ruthenium.

However, so-called pyrometallurgical metal recycling processes, which are designed for the precious metals, produce highly toxic fluorine compounds; the fluorine is contained in the membrane. That is why it is crucial to separate the polymer membrane before the melting process – but according to the researchers, there are no “recycling processes that can be used efficiently on an industrial scale” for this purpose.

In the BReCycle project, among other things, such a process is now to be developed. After dismantling and comminution (among other things by shock waves in a reactor filled with water), the fragments are to be separated into the material fractions catalyst powder and graphite as well as polymer and metals using simple physical separation processes such as sieving and filtering. From the metals, the pieces with polymer membranes are then to be removed utilizing IR sensor technology. Because of the concentration of valuable substances in the selected material groups, which is hoped for in this way, fewer chemicals will also be required in the downstream wet chemical processing.

However, to be able to process the cells and modules well at all, the researchers want to go beyond the recycling process itself and also investigate “aspects of product design suitable for recycling”. For example, the recyclability of fuel cells is to be increased as early as the design stage, and a new business model is to be developed from secondary materials obtained more simply.

After completion of the project – scheduled for completion by February 2023 – the knowledge gained is to be successively incorporated into the manufacturing processes for PEM fuel cells by the industrial partners involved. “The results from the process development will also serve as a basis for further research work to be able to establish a take-back and recycling solution, including the implementation of specific new plant modules,” the communication states.

With reporting by Sebastian Schaal, Germany.

0 Comments