GKN testing new drive in the Arctic Circle

GKN Automotive continues their tests on the 3-in-1 powertrains and has several prototypes underway in the Arctic Circle. New inverters and motors are being used in the test vehicles based on the Tesla Model 3 and Fiat Ducato.

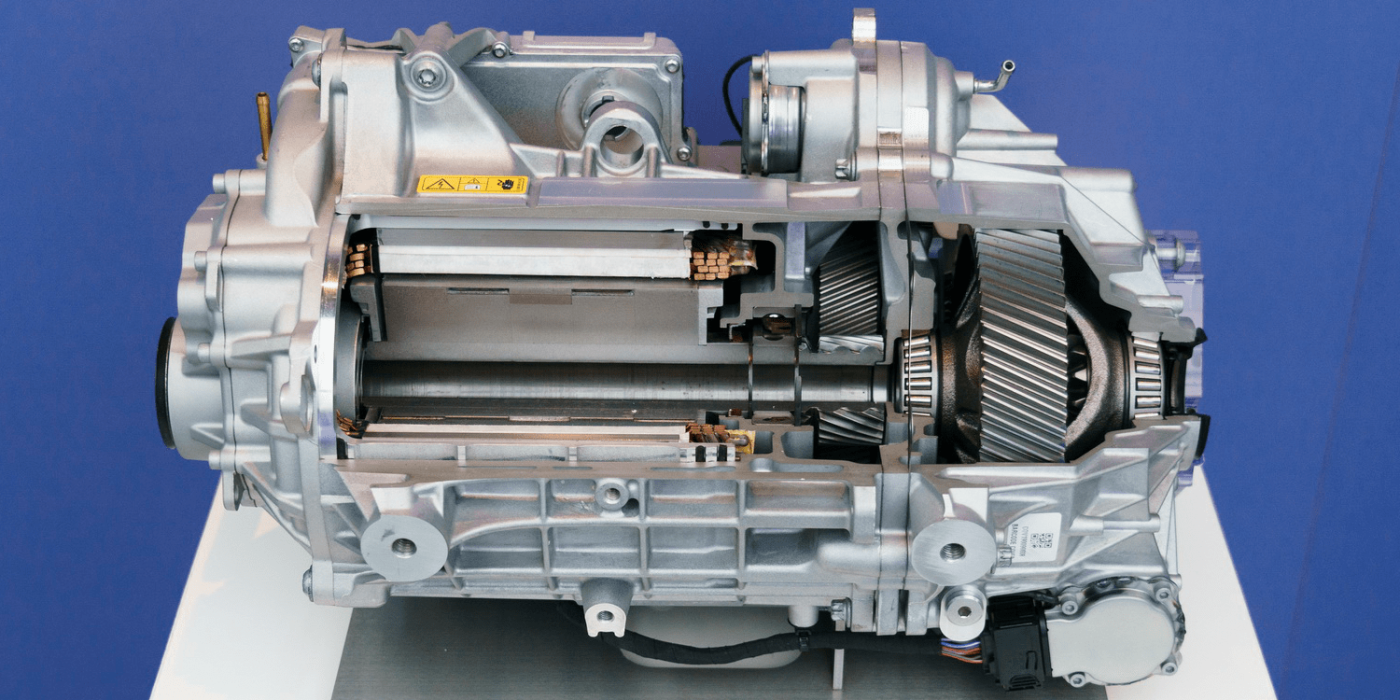

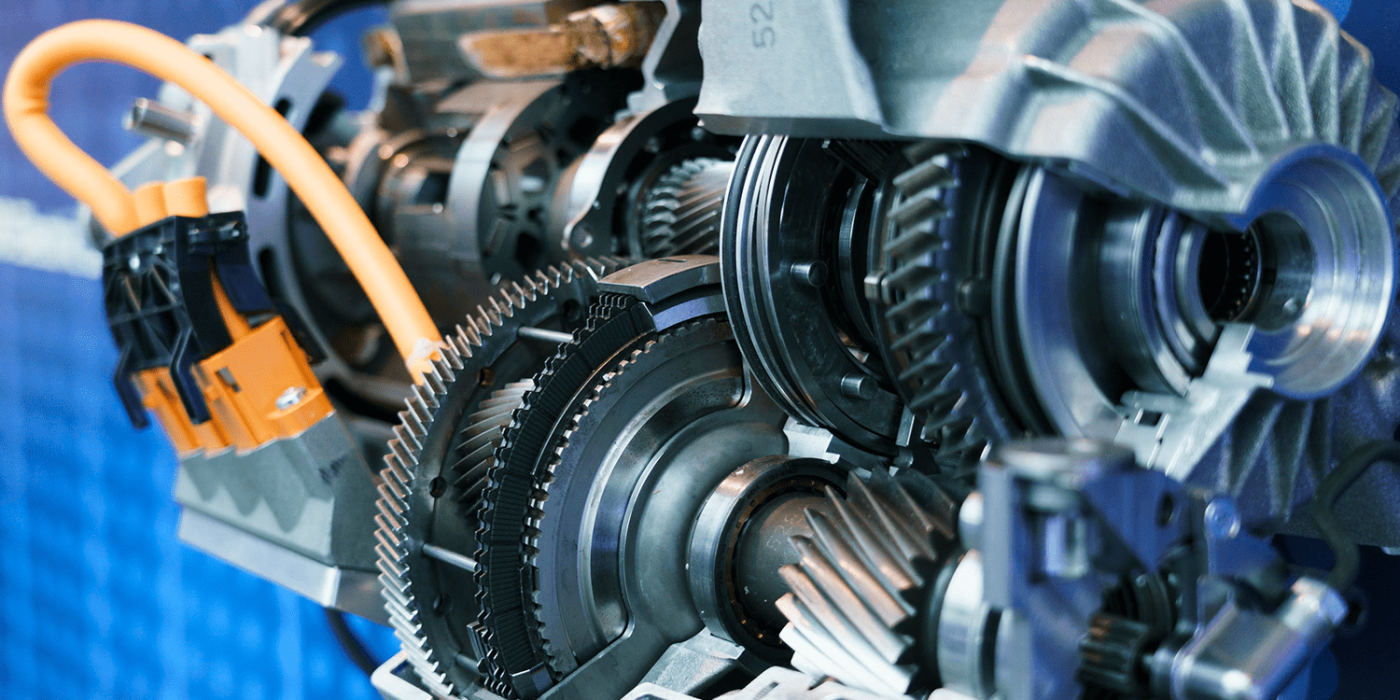

With the 3-in-1 layout of the drive unit called G400, the British supplier wants to integrate the engine, transmission and inverter in one housing – in the case of 2-in-1 drives, the inverter sits in its own housing. “By integrating our transmission and eMotor technology with Delta’s inverters into modular units, GKN Automotive is decreasing costs and reducing component packaging for automakers,” says Hannes Prenn, Technical Director of the Automotive Division of GKN Powertrain, in a press release.

GKN is currently pushing ahead with plans to set up its own electric motor manufacturing facility in Europe, and in January the British company merged its inverter development with Taiwanese company Delta Electronics. This cooperation is intended to develop the next generation of drive systems, covering a range from 80 to 155 kW.

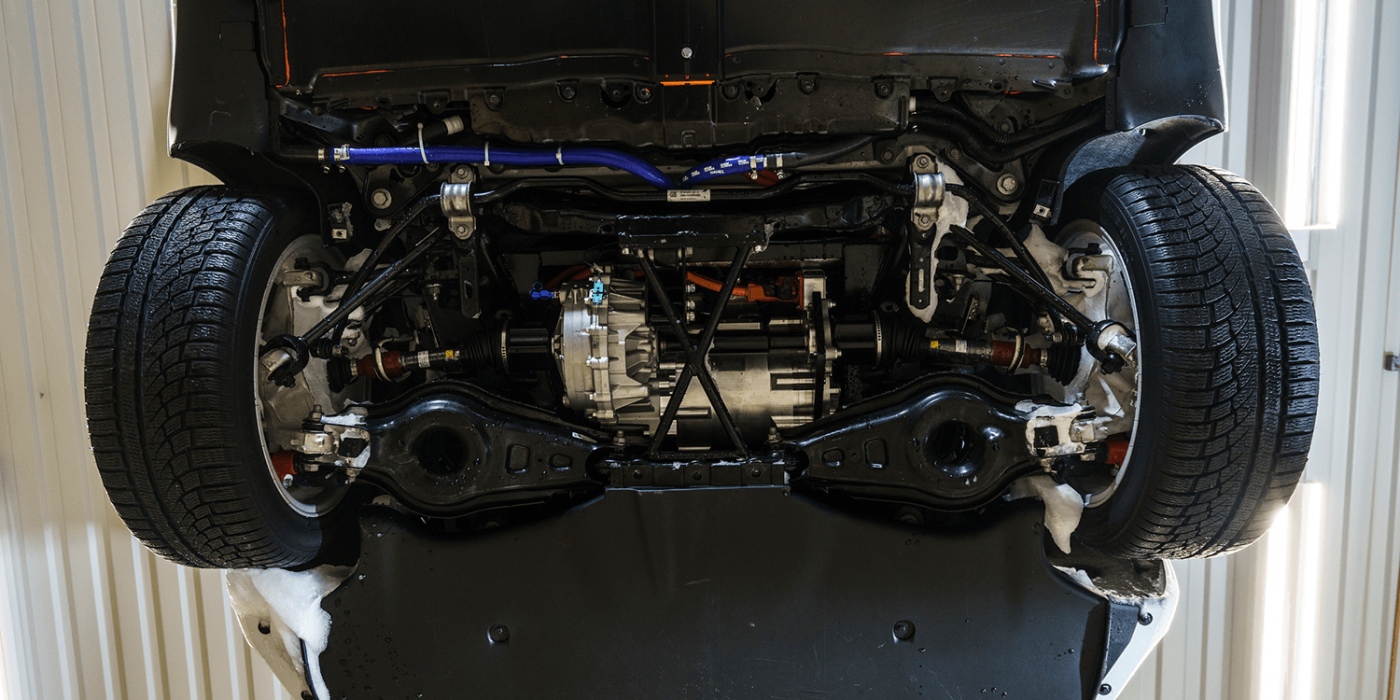

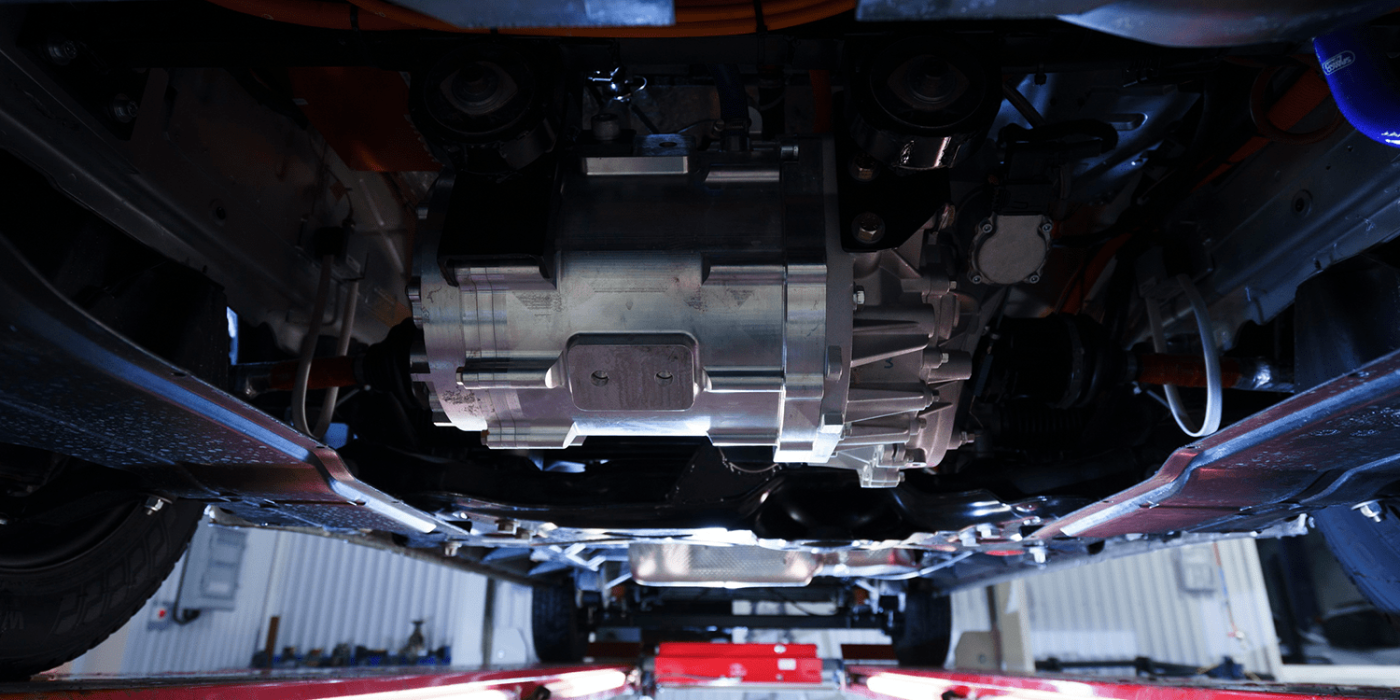

The test carriers, which are now on their way in the Swedish Arjeplog, still have a 2-in-1 drive – according to GKN it has advantages for the development work if the inverter unit is still in its own housing. But the software systems would work as if they were fully integrated. GKN also states that “full integration on the mechanical, electrical and electronic side is also well under control in terms of thermal control” – but the arrangement of the hardware (and thus potentially its thermal behaviour) does not yet correspond to the 3-in-1 layout.

GKN supplies electric drives for PSA’s PHEVs

The choice of the very different test carriers Model 3 and Ducato was made to test different arrangements – in the Tesla the G400 drive module with 126 kW is located at the rear axle, in the Fiat the drive is installed at the front. “The application of our G400 eDrive module into two very different vehicle platforms showcases how we are evolving and refining our scalable electric driveline technologies,” says Prenn. “As our order book continues to grow rapidly, we are accelerating the development of our standardised range of eDrive units to cater for a variety of platform sizes and torque requirements”.

GKN produced its millionth electric drive in June 2019. The 141 per cent increase is currently on the order list for 2020. This includes six new e-drive systems that will go into series production this year. Sales of new hybrid models from the PSA Group with GKN drive technology are also currently underway: GKN is supplying the hybrid drives for the DS 7 Crossback E-Tense 4×4, Opel Grandland X Hybrid 4 and Peugeot 3008 Hybrid 4, and GKN plans to produce one million e-drives per year by 2025.

0 Comments