Japan’s Nidec to quadruple electric motor production

Japanese electric motor manufacturer Nidec plans to invest around €1.7BN in new plants in China, Poland and Mexico to effectively increase the sales and production of electric motors from 300,000 to twelve million units.

“We want to become the number one in motors for electric cars,” Vice President Kazuya Hayafune told the German business and trade publication Handelsblatt. According to Nidec, it will already deliver 300,000 complete electric drives this year. In the long term, the company wants to produce twelve million electric drives and motors per year. The long-term growth plans are even more ambitious: By 2030, business with electric motors for cars, robots and through company acquisitions should increase sales from the current 13 to 83 billion euros.

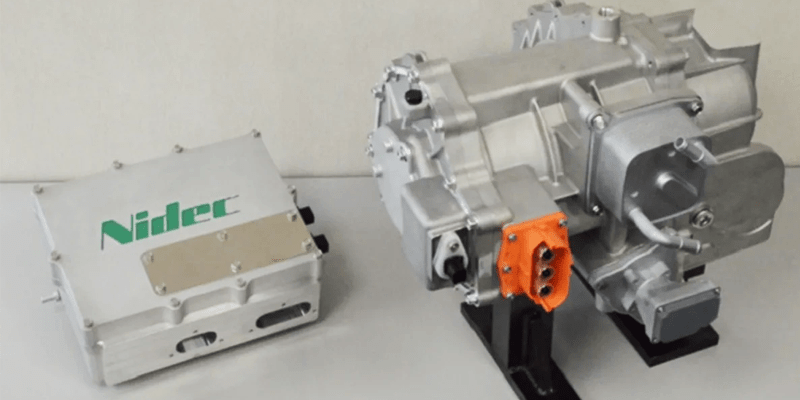

In January, the Group exhibited a complete range of five motors with outputs of 50, 70, 100, 150 and 200 kilowatts (kW) at the EV Japan trade fair. A Nidec manager told Handelsblatt that these five drives cover 98 per cent of the kinds of motors necessary for electric cars. The wide range of products is intended to appeal not only to customers from the automotive industry, but also to keep the competition small. “We want to discourage the other manufacturers,” says Hayafune. Incidentally, the Japanese manager sees the biggest competition in three Chinese low-cost brands, German giants like Bosch and Continental, and the Japanese companies Aisin and Denso.

According to Hayafune, this enormous growth will not only come from direct supplies to OEMs. Nidec could also be used in electric cars indirectly via other suppliers if their electric motors are installed in ready-to-install e-axles or entire platforms. The manager insists that “car manufacturers will order from Nidec sooner rather than later”. With mass production already in place, Nidec can produce the motors at low cost.

A significant focus for Nidec is meeting the requirements of the Chinese electric car manufacturers. Their development speed is twice as fast as that of traditional companies. In the case of electric drives, they require development cycles of only one and a half years, Hayafune said, which is why Nidec is working around the clock on the development of new motors. A first development centre recently opened in China will soon be followed by a second one, Hayafune announced in the interview.

In China, Nidec has already entered into a joint venture with a local OEM. In August 2019, the Japanese company announced the establishment of a joint venture with GAC. The electric motors from the joint venture are to be used by GAC but later also by other car manufacturers. Nidec also manufactures with partners in Europe: In November 2019, a joint assembly line with PSA was opened in France. Planned production capacity: 900,000 units.

handelsblatt.com (in German)

1 Comment