VDL & Siemens testing charging depots for utility vehicles

In an applied project, VDL and Siemens are jointly investigating how vehicle technologies, energy storage systems and charging systems interact. The focus is on efficient and flexible charging processes in depots of electric buses and trucks.

The cooperation aims to find future-oriented overall solutions for commercial vehicle depots. Siemens is supplying the latest generation of charging technology to VDL’s charging test centre in the Dutch town of Valkenswaard.

Both partners aim, among other things, to gain deeper insights into the more intelligent and efficient use of the existing power grid and the bidirectional loading of heavy-duty vehicles in the course of the project.

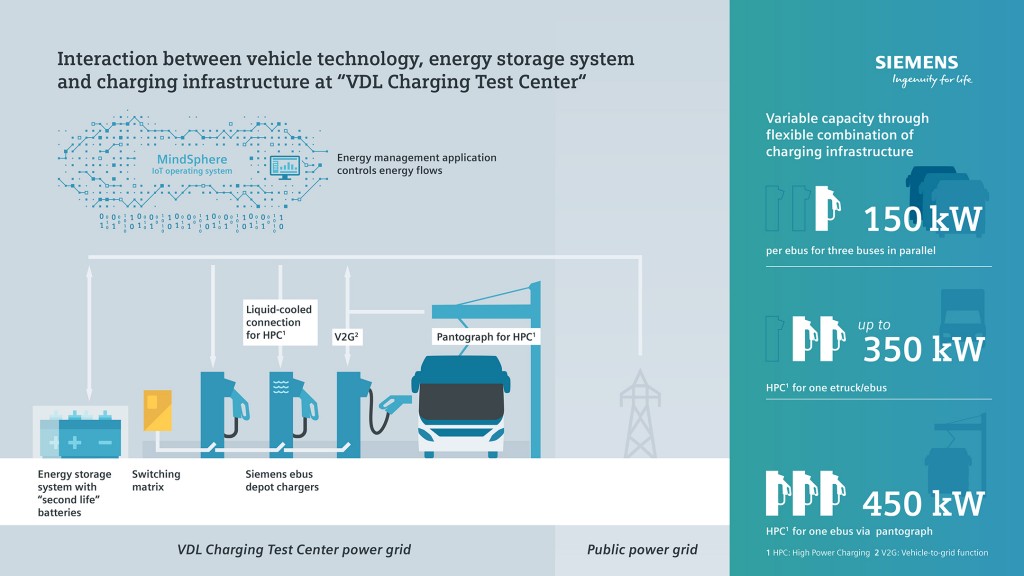

Siemens is contributing three 150 kW rapid charging stations, VDL a battery storage system for the secondary use of discarded e-bus batteries. A unique switching matrix makes it possible to interconnect the capacities of the charging stations flexibly. This allows three vehicles to be charged in parallel with 150 kW each or one vehicle to be charged particularly quickly with up to 450 kW. As shown in the diagram below, the body is controlled by an energy management app that runs on the Siemens cloud-based IoT MindSphere operating system. According to Siemens, the app makes it possible to control the energy flow as required.

Equipped in this way, VDL is now carrying out interoperability and functional tests with various electric commercial vehicles under real conditions. The Dutch company intends to test different electric bus and electric truck technologies in combination with the charging stations and the battery system. “Deployment of heavier e-vehicles also involves technical issues such as the increasing energy demand and unpredictable load on the power network,” comments Menno Kleingeld, Managing Director of VDL Enabling Transport Solutions. “It is important to use alternatives, both for smarter planning of charging times and so energy can be temporarily stored in a buffer. This temporary buffer can then supplement the available capacity of the power grid to deliver power back to the vehicles during periods of peak load.”

Another test field: A vehicle-to-grid (V2G) function is also integrated at one of the charging stations, according to an accompanying press release. Bidirectional charging – as long as it supports the vehicle – can be used to compensate for demand peaks in the power grid if such fast-charging systems are more widespread, by feeding electricity from the vehicle’s battery into the grid at short notice.

For Monique Mertins, head of the charging infrastructure division for commercial electric vehicles at Siemens Smart Infrastructure, the project with VDL is making a “step closer to making e-mobility more flexible and efficient”. The modular infrastructure in Valkenswaard shows that charging systems can be extended over a more extended time without having to adapt the network capacity or connection. “By coupling an energy storage device, charging stations and an energy management application, the capacity can be adapted to current and future needs. The project provides important insights for the electrification of the transport sector, and thus for the success of the energy turnaround”.

0 Comments