Bosch wants to use the cloud to extend battery life

Bosch is developing new cloud services that complement the battery management of vehicles so that the batteries in electric cars last longer. Intelligent algorithms are to detect battery stress factors and thus optimize charging processes, for example.

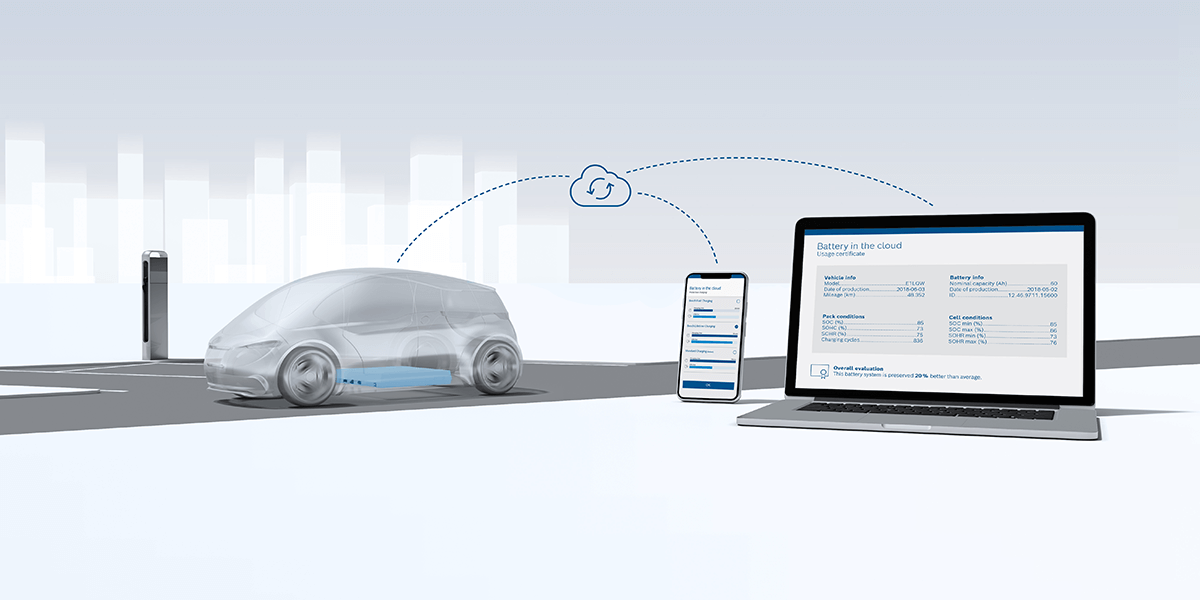

The idea: Smart software functions in the cloud continuously analyze the state of the battery and take measures against cell aging. According to Bosch, this can reduce wear by up to 20 percent. “Bosch is connecting electric-vehicle batteries with the cloud, and substantially improving performance and service life,” says Markus Heyn, Managing Director of Robert Bosch GmbH.

According to Bosch, the cloud services also use real-time data from the vehicle and its environment to optimize each individual charging process and provide drivers with customized information on a battery-saving driving style directly on the vehicle display. However, the company did not say how far Bosch would go with such recommendations. The first customer of the new services, which Bosch has grouped under the heading “Battery in the Cloud,” is the Chinese mobility provider DiDi.

Extreme temperatures and fast charging and discharging (e.g. when driving too aggressively, especially when the battery is too hot or too cold) stress the cells and cause them to age more quickly. A high charge level also increases stress. For example, Bosch wants to use its software to prevent batteries from being charged 100 per cent when it’s too hot or too cold – a charge level that is a few percentage points lower costs a little range, but, according to Bosch, increases service life enormously.

In addition, individual charging curves are to be calculated for each individual charging process. Some of this is already happening today, and Bosch says it wants to go beyond current solutions by improving the database. While the current battery management systems merely monitor and control the current status of the cells, the Bosch system will also include the charging history of the individual cells and other environmental data. This should also make it possible to carry out rapid charging, which puts the battery under less stress.

The software should also make it possible to make more accurate predictions about the service life of individual cells. If the data is evaluated not only for a vehicle, but for an entire fleet, the algorithms used can recognize even more stress factors and thus influence future development. “Powerful batteries with long services lives will make electromobility more viable,” says Heyn.

0 Comments