Nidec to double China production capacity

Japanese electric motor manufacturer Nidec plans to double its production capacity in China. In addition to a factory under construction in Zhejiang Province, Nidec will invest 20 to 30 billion yen (160 to 240 million euros) in the construction of a second production facility for traction motors.

The aim is to double the previously planned annual capacity for 600,000 to 700,000 cars. The first factory is to go into operation in May, the second in 2020. Interestingly, Nidec wants to produce engines in the second factory that are about 30 percent smaller than those from the first site – a step towards taking up less space in customers’ vehicles and also driving smaller vehicles.

Speaking of customers: Nidec’s customers include the Chinese manufacturer GAC, which is the first OEM to use Nidec’s fully integrated electric axle in series production for its debut electric car, the Aion S. The Chinese manufacturer is the first OEM to do so. In the future, the supplier also wants to win European market participants as customers. OEMs from all over the world have already inquired, Nidec recently announced. It is rumoured that the company is also considering building a factory in Poland.

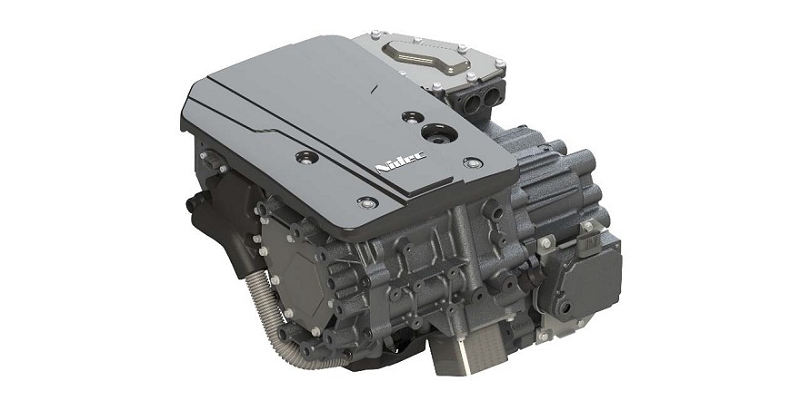

Nidec’s electric axle consists of an electric machine, gearbox and inverter. The presentation in April 2018 revealed that the electric drive system weighs only 83 kilos, with a maximum output of 150 kW and a maximum torque of 3,900 Nm. According to the manufacturer, the system will be suitable for a wide range of applications – from small cars to SUV platforms.

For the financial year 2025, the Japanese are also aiming for sales of 200 billion yen (1.6 billion euros), with the automotive supply sector becoming an increasingly important business segment. In the spring of 2018, Nidec and the PSA Group also concluded the establishment of a joint venture for the development, production and sale of traction motors for use in electric and hybrid cars. The aim is to achieve an annual production capacity of 900,000 electric machines by 2022.

0 Comments