Researchers adapt flexible bipolar plates in batteries

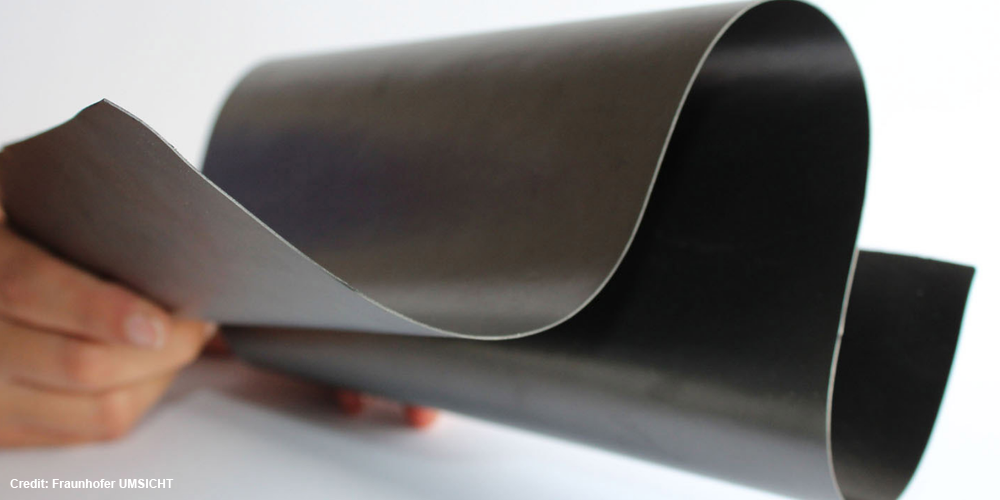

Researchers from the German Fraunhofer Institute for Environmental, Safety and Energy Technology (UMSICHT) have announced a new development in battery technology, using a “new type of flexible and extremely thin bipolar plate allows batteries to be manufactured cost-effectively.”

The institute presents the battery technology as far more simple, and thus less prone to problems such as overheating. Also, the packaging material used on battery components would be reduced, allowing for a more efficient battery design, which could save valuable space and weight in vehicle development.

“We manufacture bipolar plates from polymers that have been made electrically conductive,” says Dr Anna Grevé, department head at Fraunhofer UMSICHT. “In this way, we can produce very thin plates and – compared with conventional cells connected by wires – save over 80 percent of the material used.” The newly developed plates have apparently effectively addressed the challenges in the method, which included problems with corrosion or size. Furthermore, the plates are so resistant to thermal and mechanical stress, that they can be welded together, allowing for tighter battery construction.

2 Comments