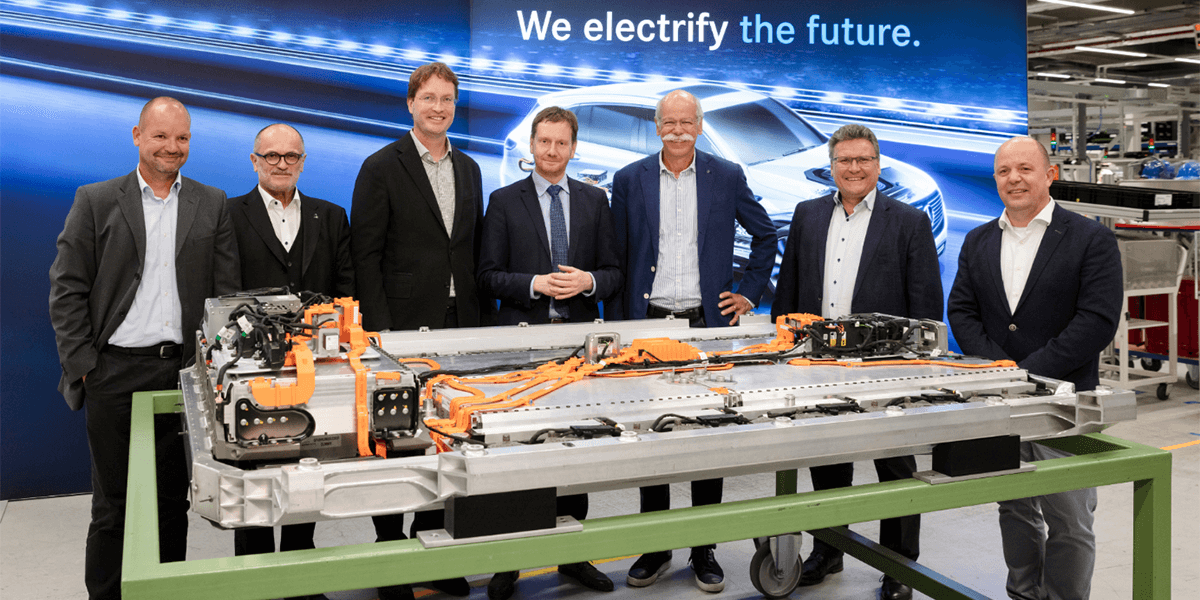

Daimler doubles workforce at battery factory a year early

Daimler’s battery subsidiary Accumotive say they will double the workforce at the Kamenz plant before the year’s end – a year ahed of schedule. 1,000 employees will then assemble battery packs for the upcoming Mercedes EQC, while Daimler is also setting up a second battery factory at the moment.

Daimler has been planning to secure their battery supply chain in earnest since 2016. Cell production does not play a role but assembly is done by their subsidiary Accumotive. The latter now announces they would complete doubling their workforce this year, twelve months earlier than initially planned.

The site in Kamenz has produced 200,000 battery packs from 2012 to date, reads a release. Frank Deiß, Head of Production Mercedes-Benz Cars, adds that over the years of producing batteries, they “have gained valuable knowledge”. He added “Our team is working highly motivated on a daily basis and is coping with the increasing quantities while operating the new systems”. Clearly, the site is being ramped up pretty fast and from 2019 onwards it will manage the volume production of batteries for the fully electric Mercedes-Benz EQC. The electric SUV is expected to hit the market by mid-2019.

But, the Accumotive plant in Kamenz, around 50 kilometres away from Dresden, Saxony, also makes batteries for Smart electric vehicles. Moreover, Daimler is investing another half a billion euros at this site, where at present a second battery factory is being built. This will be one of the largest and most modern battery factories worldwide, according to the carmaker.

Globally, Daimler is investing more than one billion euros in a battery production network with a total of eight factories at six locations and on three continents reportedly. This includes in Germany Kamenz and Stuttgart-Untertürkheim with two battery factories each as well as Sindelfingen, Peking (China), Bangkok (Thailand) and Tuscaloosa (USA).

0 Comments