Audi and Umicore develop closed loop battery recycling

Audi and Umicore are developing a closed loop for the recycling of high voltage batteries from electrified vehicles, which can be reused again and again. Particularly valuable materials, including cobalt, nickel and copper, will be stored in a resource bank.

An analysis by the partners showed that 95% of the battery materials, such as cobalt, nickel and copper can be recycled. With this step, they have completed the first phase of the strategic research cooperation for battery recycling.

Already ahead of the begin of the cooperation with Umicore in June 2018, Audi had analysed the batteries from their plug-in hybrid A3 e-tron, and defined several recycling options. Together with the technology material experts, the German manufacturer has determined potential recycling quotas for battery components, resulting in the previously mentioned 95% reclamation rate.

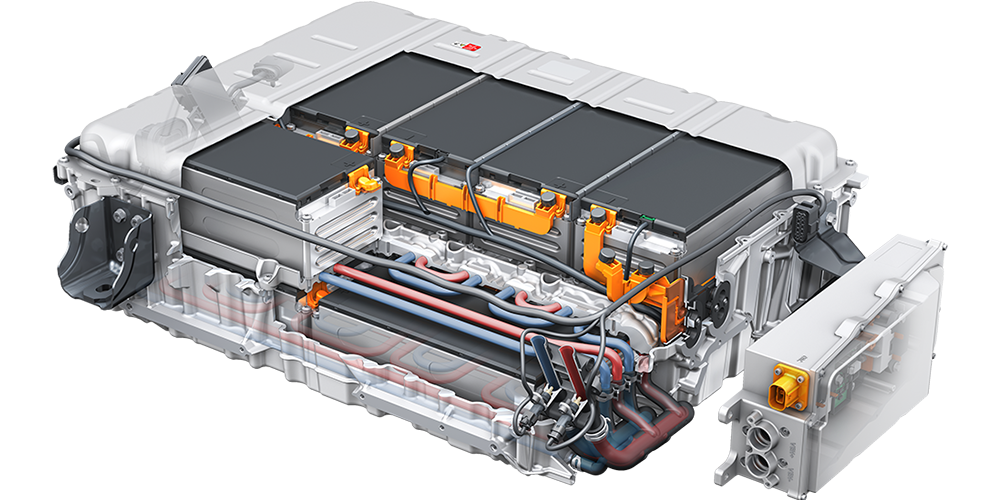

Now the partners are developing more concrete recycling concepts. In the centre of the initiative stands the so-called closed-loop approach. This kind of process uses valuable elements from batteries at the end of their life cycle for new products, allowing for further use. This approach will now be implemented for batteries in the new Audi e-tron. The insights won from the process will be used to establish the available purity of the re-used resources, and establish a recycling quota and the commercial viability for concepts such as the resource bank. Supply reliability and shorter supply and transportation lines are the intended goal.

Umicore has recently also started a consortium with BMW and Northvolt to jointly develop a complete value chain for electric vehicle battery cells in Europe. The goal of the combined effort is now to connect the different competency fields of cell chemistry and development to production to the recycling of the components, establishing a know-how, which could prove essential to setting up European battery cell manufacturing capacities.

0 Comments