Hi-tech stacking to make large-format Li-ion cells at ZSW

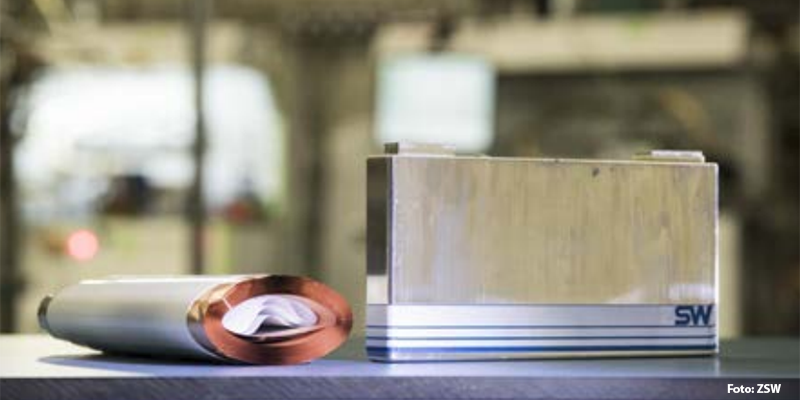

ZSW is piloting a novel manufacturing method for Li-ion cells. A new line now opened in Ulm, Germany, enables the researchers to stack rather than wind the electrode strips in order to enhance cell properties.

Together with the industry, the scientists at the Centre for Solar Energy and Hydrogen Research Baden Württemberg (ZSW) in Ulm want to establish stacking as a new technology in Germany. The project called STACK kickstarts this January. Funded with 2.7 euros through the Federal Ministry of Education and Research (BMBF) it will run for three years.

Already the lines at ZSW assemble prismatic cells with wound electrodes (PHEV-1 format) in a fully automated workflow. The new project STACK aims to build on that and to develop an ultra-fast manufacturing process using both a novel production line and new materials. ZSW plans to deploy a high-tech stacker and separator to produce and evaluate sample cells in PHEV-1 format on an industrial scale.

For now, the pilot line serves as research platform for companies in order to develop their own manufacturing processes. Eventually, stacking is to lead to a “cost-effective mass production of large Li-ion cells,” according to Professor Werner Tillmetz, member of ZSW’s board of directors and head of the Electrochemical Energy Technologies division.

Manz and Freudenberg are ZSW’s initial industrial partners.

0 Comments